TABLE OF CONTENTS

- Reality of Durability and Maintenance of Exterior Wood Cladding

- Factors Affecting the Durability of Exterior Wood Cladding

- Advanced Technologies and Treatments to Extend Service Life

- Installation Systems as a Determining Factor in Durability

- Maintenance Based on Finish Types and Environmental Conditions

- Technical Solutions for Resistance to Biological Factors

- Innovations in UV Protection and Color Stability

- Performance of Cladding in Extreme Weather Conditions

- Maintenance-Free Exterior Wood Systems

- Relationship Between Sustainability and Durability in Exterior Cladding

- Frequently Asked Questions

1. Reality of Durability and Maintenance of Exterior Wood Cladding

The incorporation of natural wood in exterior facades represents an architectural decision that combines aesthetic, functional, and bioclimatic values. However, continuous exposure to environmental factors poses significant technical challenges that determine the long-term durability and performance of these systems. Current regulatory requirements and the pursuit of sustainable architectural solutions have driven the development of advanced technologies that overcome the traditional limitations of exterior wood cladding, particularly in terms of durability and maintenance.

This document addresses contemporary solutions to maximize the durability of exterior wood cladding, analyzing both the intrinsic properties of the material and the systems for protection, installation, and maintenance. The focus is on solutions tailored to the needs of the professional architectural sector, where technical durability must be complemented by aesthetic stability and reduced maintenance cycles.

2. Factors Affecting the Durability of Exterior Wood Cladding

The durability of exterior wood cladding is influenced by a complex interplay of factors that must be considered during the project specification phase:

Environmental Factors

Solar radiation, particularly UV rays, causes photochemical degradation of lignin, leading to surface color changes and, over time, the breakdown of surface fibers. Additionally, wet-dry cycles generate dimensional stresses that can result in deformations, cracks, and separation between elements. The combined effect of precipitation and wind increases surface erosion, while atmospheric pollution can accelerate degradation processes, especially in urban and industrial environments.

Biological Factors

Colonization by wood-destroying fungi, both chromogenic and rot-causing, is directly linked to sustained moisture content above 20%. Wood-boring insects, such as anobids, cerambycids, and termites, pose another significant threat, particularly in temperate and warm regions, where they can compromise the material’s structural integrity. Additionally, the formation of microorganism biofilms (algae, lichens) primarily affects aesthetics but can contribute to elevated moisture levels that facilitate biological degradation.

Intrinsic Factors of Wood

Natural durability varies significantly among species, ranging from those classified as “highly durable” (Class 1 per EN 350) to “non-durable” (Class 5). Density, natural extractive content, porosity, and anatomical structure decisively influence the material’s inherent resistance to degrading agents. The orientation of growth rings in installed pieces also affects dimensional stability and the tendency to develop deformations under hygroscopic changes.

3. Advanced Technologies and Treatments to Extend Service Life

Technological advancements have enabled the development of treatments that modify wood’s behavior against degrading factors while preserving its aesthetic qualities:

Thermal Modification

Thermal modification is one of the primary innovations implemented on an industrial scale. This process, conducted in controlled atmospheres at temperatures between 160°C and 240°C, induces chemical changes in the molecular structure of cellulose, hemicellulose, and lignin. The result is greater dimensional stability (40-50% reduction in hygroscopic movement), lower hygroscopicity, and a significant increase in biological durability. Species such as ash, ayous, or pine, which naturally have low durability, can achieve durability classifications of Class 1-2 after this treatment.

Acetylation Treatments

Acetylation treatments involve replacing hydroxyl groups with acetyl groups through a reaction with acetic anhydride, drastically reducing the wood’s ability to absorb water. This leads to enhanced resistance to biological degradation and improved dimensional stability. Commercially available panels with this technology have demonstrated durability exceeding 50 years under extreme exposure conditions.

Impregnation with Thermosetting Resins

Impregnation with thermosetting resins represents another significant innovation. Systems like those implemented by Parklex Prodema in their NATURCLAD-W panels combine natural wood veneers with phenolic resins subjected to high pressure and temperature, creating a compact material with enhanced properties. The inclusion of specific additives during manufacturing results in products with improved UV resistance, color stability, and anti-graffiti properties.

Nanotechnologies

Nanotechnologies applied to surface coatings are experiencing rapid development, with solutions incorporating metal oxide nanoparticles (ZnO, TiO2) that provide photocatalytic, hydrophobic, and antimicrobial properties. These cutting-edge coatings can exponentially increase the material’s durability without affecting its natural appearance.

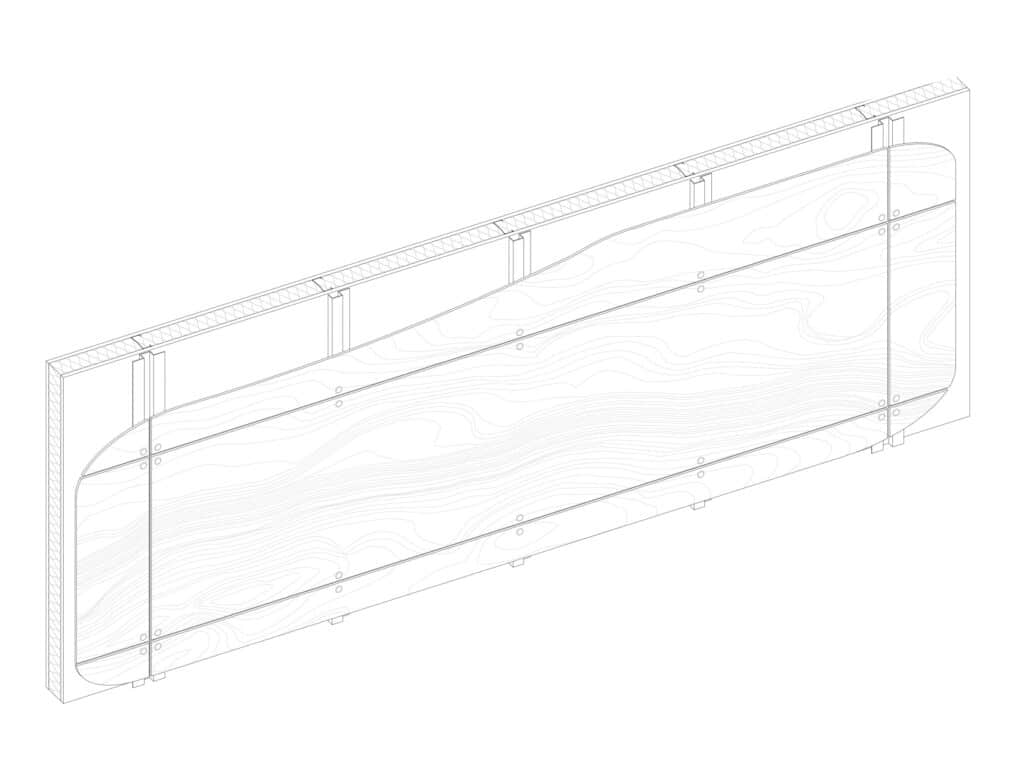

4. Installation Systems as a Determining Factor in Durability

Proper installation is as critical to durability as the intrinsic quality of the material and its treatments. Ventilated facade systems are the optimal solution for exterior wood cladding because they:

- Facilitate rapid moisture evacuation through an air gap (minimum 20mm as per technical standards like Spain’s CTE)

- Ensure constant ventilation to balance hygrothermal conditions on both sides of the cladding

- Minimize the effects of interstitial condensation that could affect the material

Fastener systems must be designed to account for the material’s specific hygroscopic behavior. Hidden fastener systems with clips or hooks, such as those used in Parklex Prodema’s NATURCLAD and NATURSIDING panels, allow for natural dimensional movement without inducing excessive stress at fastener points. To ensure these systems function correctly:

- A minimum 20 mm gap between the cladding and the rear wall must be maintained

- Water evacuation systems at the base and top of the facade are essential

- Fasteners must allow dimensional movement without restriction

Incorporating fixed and floating anchor points is crucial to balance positional stability with the freedom of movement needed to accommodate dimensional variations. For panels measuring 2440×1220 mm, perimeter joints of at least 6-8 mm must be maintained, avoiding sealing with flexible materials that could accumulate dirt.

5. Maintenance Based on Finish Types and Environmental Conditions

Maintenance requirements vary significantly depending on the type of finish and environmental exposure conditions:

Cladding with Natural Finishes

For cladding with natural finishes (without specific surface treatments), a natural chromatic aging process occurs, progressing toward grayish tones. This process, which many architects incorporate as a design element, can be managed through:

- Periodic cleaning with low-pressure water (maximum 1500 psi) to remove biological deposits

- Biennial application of penetrating natural oils with fungicides in humid climates

- Finish renewal every 3–5 years in areas with high solar exposure

Cladding with Advanced High-Performance Finishes

Cladding with advanced finishes, such as Parklex Prodema’s NATURCLAD-W panels, which incorporate PVDF (polyvinylidene fluoride) treatments and anti-graffiti overlays, does not undergo chromatic aging and requires no maintenance, such as:

- Cleaning with water and neutral detergent to remove surface dirt

- No need for finish renewal or protective applications

- Proven resistance to graffiti stains, allowing removal without aesthetic damage

The facade’s orientation is a critical factor in maintenance planning, with south and west facades (in the northern hemisphere) experiencing greater degradation due to UV radiation and requiring more frequent maintenance cycles. Similarly, proximity to marine environments, with exposure to saline aerosols, increases maintenance demands and requires highly corrosion-resistant metal fasteners(A4 stainless steel or higher).

6. Technical Solutions for Resistance to Biological Factors

Protecting exterior wood cladding from biological degrading agents is one of the main challenges in ensuring durability. Contemporary solutions combine preventive and active strategies:

Proper selection of wood species based on their natural durability, classified according to EN 350, optimizes performance against fungi and insects depending on the use class. Species such as iroko, teak, red cedar, or ipé (Class 1-2) offer natural resistance in exterior applications without additional treatments, though they undergo chromatic variations due to natural aging.

Next-generation biocidal treatments are characterized by high effectiveness at low concentrations and minimal environmental impact. Fourth-generation preservatives, based on micronized copper and organic co-biocides, provide effective protection while complying with European regulations (BPR Regulation 528/2012). These treatments are applied through vacuum-pressure impregnation processes in autoclaves, ensuring controlled penetration.

For environments with a high risk of termite attack, particularly in Mediterranean, subtropical, and tropical regions, specific solutions include:

- Physical barriers integrated into ventilated facade systems

- Treatments with microencapsulated permethrin for gradual release

- Preventive monitoring through early detection systems

Compact systems, such as NATURCLAD-W panels, incorporate protective layers that act as a physical barrier against biodegradable agents, combined with cores treated with resins that chemically modify the substrate, making it unsuitable for wood-destroying organisms.

7. Innovations in UV Protection and Color Stability

Ultraviolet radiation degradation is one of the primary factors affecting the aesthetic durability of exterior wood cladding. Innovations in this field have enabled the development of solutions that maintain the original appearance for significantly longer periods:

- Next-generation UV filters use HALS (Hindered Amine Light Stabilizers) technology combined with inorganic UV absorbers to neutralize free radicals generated by photodegradation, protecting the wood’s lignin. These systems can be incorporated into surface treatments or integrated into the resin matrix of composite panels, providing in-depth protection.

- Transparent metal oxide pigments represent another significant innovation, preserving the natural texture and grain of the wood while offering effective UV protection. Unlike traditional pigments, these selectively filter the most harmful wavelengths without concealing the natural grain.

- Multilayer systems with PVDF (polyvinylidene fluoride) technology, integrated into products like Parklex Prodema’s NATURCLAD-W panels, provide an effective barrier against UV degradation while maintaining the visual characteristics of natural wood. Accelerated aging tests per EN ISO 16474-2 (formerly EN 927-6) demonstrate that these systems can maintain color stability up to five times longer than conventional treatments.

Color stabilization through UV-catalyzed systems offers significant advantages, particularly for corporate architecture and institutional projects where long-term chromatic consistency is critical. These systems create stable chemical bonds that resist photodegradation, preserving the original appearance for extended periods.

8. Performance of Cladding in Extreme Weather Conditions

Extreme weather conditions pose specific challenges for exterior wood cladding, requiring tailored technical solutions: In alpine and subarctic climates with frequent freeze-thaw cycles, the main considerations are:

- Installation systems that allow ice expansion without generating structural stresses

- Resistance to impacts from ice or snow accumulation and falling

- Compatibility with high thermal insulation construction systems

High-density panels, such as those in Parklex Prodema’s NATURCLAD series, have demonstrated excellent performance in these conditions, as evidenced by their use in architectural projects in alpine regions of Europe and North America. In coastal and marine environments, the combination of saline aerosols, high humidity, and intense UV radiation accelerates degradation processes. Technical solutions must include:

- Exclusive use of A4 stainless steel or higher-grade fasteners

- Optimized drainage systems in the ventilated cavity

- Surface treatments with hydrophobic properties to minimize saline water absorption

In desert regions with high solar radiation, where surface temperatures of the cladding can exceed 80°C, it is essential to:

- Select systems with verified dimensional stability under extreme conditions

- Implement larger ventilated cavities (minimum 40mm) to reduce surface temperatures

- Consider complementary shading systems

Technical documentation for cladding systems must clearly specify performance limits in extreme conditions, including data verified through standardized tests, such as accelerated aging cycles per EN 321.

9. Maintenance-Free Exterior Wood Systems

The development of exterior wood cladding systems that virtually eliminate maintenance requirements represents one of the most significant innovations for the architectural sector.

High-performance natural wood panels, such as those developed by Parklex Prodema, offer a comprehensive solution combining the aesthetics of natural wood with advanced technical properties. The manufacturing technology, involving high-pressure pressing (>100 kg/cm²) and high temperatures (>150°C) with thermosetting resins, creates a compact material where the natural wood veneer is protected by technical layers that provide:

- Extreme resistance to UV radiation without significant chromatic changes

- Surface impermeability to prevent water absorption

- A physical barrier against biological agents

- Non-porous surfaces that prevent dirt accumulation

These systems have proven to maintain their aesthetic and functional properties for over 10 years with no maintenance beyond basic cleaning, as demonstrated in landmark projects like the Guggenheim Museum in Bilbao and various applications in international airports.

Chemically modified wood through processes like acetylation or furfurylation undergoes permanent molecular changes that eliminate reactive sites (primarily hydroxyl groups) responsible for water absorption and biological degradation. These products offer guarantees of up to 50 years without maintenance in exterior applications, retaining the natural texture and appearance of wood, though with progressive darkening due to UV exposure.

Hybrid systems combining naturally durable species with high-tech surface treatments and optimized installation systems represent another low-maintenance alternative, particularly suitable for projects requiring large surfaces or tight budgets.

10. Relationship Between Sustainability and Durability in Exterior Cladding

The technical durability of exterior wood cladding is a critical factor in its overall environmental impact, establishing a direct relationship between technical performance and sustainability:

Service Life of Cladding

Life Cycle Assessment (LCA) demonstrates that extending service life has a greater impact on reducing environmental footprint than selecting materials with lower initial impact but reduced durability. A cladding system with a 50-year service life, compared to alternatives requiring replacement every 15–20 years, significantly reduces:

- Consumption of natural resources

- Emissions associated with manufacturing, transportation, and installation

- Generation of construction and demolition waste

Technically modified wood and compact panels, despite involving more energy-intensive industrial processes than untreated natural wood, can be environmentally preferable when considering the full life cycle. This is particularly relevant for institutional and public buildings with extended time horizons.

Sustainability Certifications

Sustainability certifications in construction (LEED, BREEAM, …) increasingly incorporate durability and maintenance criteria as key factors in environmental assessment. Specifying systems like NATURCLAD-W panels, which have verified Environmental Product Declarations (EPDs) per ISO 14025 and PEFC certification ensuring sustainable wood sourcing, positively contributes to achieving these certifications.

11. Frequently Asked Questions

What is the expected service life of an exterior wood cladding system with advanced technology?

Advanced systems like Parklex Prodema’s NATURCLAD-W panels come with a 10-year warranty and an estimated service life exceeding 25 years without significant degradation under normal exposure conditions. This durability can be extended with basic cleaning maintenance that does not require finish renewal. The actual service life depends on specific exposure conditions, with orientation, altitude, proximity to marine environments, and installation quality being determining factors.

What is the difference between conventional surface treatments and wood modification technologies in terms of durability?

Conventional surface treatments (varnishes, lasures) create a protective film that degrades over time due to the combined effects of UV radiation and hygrothermal cycles, requiring periodic renewal (typically every 2–5 years). In contrast, modification technologies permanently alter the chemical and/or physical structure of the wood, eliminating or neutralizing intrinsic degradation mechanisms. This results in solutions where durability does not rely on maintaining a surface layer but on stable changes within the material itself.

How does architectural design influence the durability of exterior wood cladding?

Architectural design is critical to maximizing durability. Elements such as properly sized overhangs, efficient drainage systems, construction details that prevent water accumulation, and proper ventilation of the rear cavity can double the cladding’s service life. Similarly, considering solar orientation and exposure to prevailing winds during system specification optimizes long-term performance.

What specific considerations are required for projects in marine or high-salinity environments?

Marine environments combine multiple aggressive factors: high humidity, wet-dry cycles, saline aerosols, and often intense UV radiation. For these environments, it is recommended to:

- Select systems with verified resistance to marine environments (Service Class 3.2 per EN 335)

- Use only A4 stainless steel or higher-grade fasteners

- Implement construction details ensuring rapid water evacuation

- Consider naturally durable species (Class 1 per EN 350) or technically modified systems with verified resistance, such as NATURCLAD-W

What are the key European standards for evaluating the durability of exterior wood cladding?

Key standards include:

- EN 350: Classification of the natural durability of wood species

- EN 335: Definition of use classes and biological risk

- EN ISO 16474-2: Accelerated aging tests for UV radiation

- EN 927: Evaluation of coatings for exterior wood

- EN 717: Formaldehyde emissions from wood-based products

- EAD 090119-00-0404: European Assessment Document for exterior cladding in ventilated facades