TABLE OF CONTENTS

- 1. International Technical Standards for Wood Finishes

- 2. Physical-Mechanical Properties and Their Relevance in Specification

- 3. Resistance to Adverse Weather Conditions

- 4. Performance Combating Fire: Classification and Requirements

- 5. Sustainability and Environmental Certifications

- 6. Durability and Maintenance

- 7. Acoustics and Thermal Insulation

- 8. Compatibility with Construction Systems

- 9. Technical Documentation for Professional Specification

- 10. Frequently Asked Questions

1. International Technical Standards for Wood Finishes

Proper specification of wood finishes for architectural projects demands thorough knowledge of current regulations. Technical standards set objective parameters that enable the evaluation and comparison of the performance of different systems available on the market.

The main regulatory framework for wood cladding in ventilated facades includes:

- EN 438-6:2016 – Defines the requirements for decorative high-pressure laminates (HPL) for outdoor use, establishing criteria to evaluate properties such as dimensional stability, weather resistance, and UV behavior.

- EN 13501-1 – Establishes the fire classification of construction products, categorizing materials according to their contribution to fire development.

- DIN 4108-3 – German standard that regulates moisture protection and sets criteria for energy efficiency in buildings.

- ASTM D2244 – American standard that determines the method for evaluating color differences on surfaces exposed to environmental conditions.

- UNE-EN 335 – Determines the use classes and durability of wood and wood-based products.

It is essential to highlight that high-quality wood cladding, such as Parklex Prodema’s NATURCLAD panels, undergoes rigorous testing in accordance with these standards, obtaining certifications that validate their technical performance under real conditions. These tests include accelerated aging cycles that simulate exposure equivalent to 10 years or more in severe climatic conditions.

2. Physical-Mechanical Properties and Their Relevance in Specification

Physical-mechanical properties determine the structural behavior and durability of wood finishes throughout their service life. These properties are especially relevant in facade applications, where materials are exposed to wind loads, impacts, and thermal deformations.

Flexural Strength and Modulus of Elasticity

Flexural strength (expressed in MPa) indicates the panel’s ability to withstand loads perpendicular to its surface. High-density natural wood panels typically exhibit values between 100–150 MPa, substantially higher than those of untreated natural wood. This property is decisive in determining the spacing between fastening points and the overall strength of the system.

Dimensional Stability

A critical factor for wood finishes is dimensional stability in the face of changes in humidity and temperature. It is expressed through coefficients that quantify dimensional variation:

- Coefficient of linear thermal expansion: typically between 2.5-3.0 x 10⁻⁵ K⁻¹

- Dimensional variation due to humidity changes: less than 0.3 % in high-quality products

Advanced wood finish systems incorporate treatments that minimize these movements, allowing for smaller expansion joints and greater precision in execution.

Density and Impact Resistance

Material density (kg/m³) directly influences impact resistance. High-performance exterior cladding panels usually have densities between 1,350–1,500 kg/m³, significantly higher than those of traditional solid wood. This provides excellent resistance to impacts, evaluated through standardized tests such as the large-diameter ball impact test (EN 438-2:21).

These mechanical properties must be considered as an integral system together with the fastening elements and subframe, since the overall performance of the cladding will depend on how all these elements interact under different stresses.

3. Resistance to Adverse Weather Conditions

The durability of wood cladding under outdoor conditions is one of the most critical technical aspects in architectural specification. Continuous exposure to UV radiation, precipitation, freeze-thaw cycles, and atmospheric pollutants can significantly degrade the aesthetic and mechanical properties of conventional cladding.

Technical wood panels for exterior cladding incorporate multiple protective layers that ensure resistance to:

- Ultraviolet radiation: Ultraviolet radiation: PVDF (polyvinylidene fluoride) coatings and specific resins in the panel composition provide exceptional protection against solar degradation. The EN 438-2:29 standard evaluates this behavior through accelerated exposure cycles that simulate years of outdoor use.

- Humidity and Thermal Cycles: The stratified structure of wood panels such as NATURCLAD, with a core of cellulose fibers impregnated with phenolic resins and treated natural wood veneers, provides exceptional stability against sudden changes in temperature and humidity. These panels maintain their structural integrity even after prolonged exposure to water immersion and drying cycles.

- Abrasion Resistance: Surface coatings with anti-graffiti technology not only protect against vandalism but also significantly increase abrasion resistance. Tests according to EN 438-2:25 demonstrate that these panels can withstand more than 350 cycles without showing appreciable surface deterioration.

Specialized manufacturers subject their products to accelerated aging tests in accordance with EN ISO 4892-2, which includes cycles of artificial radiation exposure, water spraying, and temperature control. These tests reliably predict the long-term performance of panels under real conditions.

The surface treatment of Parklex Prodema panels also incorporates a component that provides exceptional color stability benefits under all weather conditions, eliminating the need for varnishes throughout their service life.

4. Performance Combating Fire: Classification and Requirements

Fire safety is a fundamental aspect in the specification of wood finishes, especially in high-rise buildings or those with specific evacuation requirements. High-performance wood cladding has developed advanced solutions that overcome the traditional limitations of natural wood in this area.

European Fire Reaction Classification

The European system classifies materials according to EN 13501-1, establishing the following categories relevant to facade cladding:

- A1 and A2: Non-combustible materials or with very limited contribution to fire

- B: Very limited contribution to fire

- C: Limited contribution to fire

- D: Medium contribution to fire

- E: High contribution to fire

- F: No performance determined

This main classification is supplemented by additional indicators:

- s1, s2, s3: Smoke production (s1 = most favorable)

- d0, d1, d2: Falling droplets/inflamed particles (d0 = most favorable)

Parklex Prodema’s fire-resistant GRCLAD-W panels achieve B-s1,d0 classification, and GRCLAD-B panels achieve A2-s1,d0 classification, allowing their use in high-rise buildings under the most stringent regulations. These panels incorporate a fiberglass core impregnated with synthetic resins and mineral filler, making them non-combustible and replacing the original cellulose layer.

Country-specific Regulations and Applications

In addition to the European classification, specific regulations must be considered:

- ASTM E84 (United States): Establishes test methods for surface burning characteristics

- NFPA 285 (United States): Test method for evaluating fire propagation in facades

- BS 8414 (United Kingdom): Fire performance test for facade cladding

Proper specification of wood finishes must consider not only the behavior of the isolated panel but also the complete system, including subframe, insulation, and ventilated cavity. Full-scale tests according to these standards evaluate the overall system performance.

5. Sustainability and Environmental Certifications

The integration of sustainability criteria in architectural specification has shifted from being an option to becoming a regulatory requirement in many markets. Wood finishes offer inherent benefits in this area, but it is essential to verify their origin and manufacturing process through recognized certifications.

Sustainable Forest Management Certifications

The main certifications that guarantee the sustainable origin of wood are:

- PEFC (Programme for the Endorsement of Forest Certification): An international system that promotes sustainable forest management through independent certifications.

- FSC (Forest Stewardship Council): Certifies that products come from forests managed with environmentally appropriate, socially beneficial, and economically viable criteria.

Parklex Prodema products hold both certifications, ensuring that the wood used comes from sustainably managed forests.

Environmental Product Declarations (EPD)

EPDs (Environmental Product Declarations) provide verified and transparent information on the environmental impact of products throughout their life cycle, in accordance with ISO 14025. These declarations include quantified data on:

- Global warming potential (kg CO₂ eq.)

- Energy resource consumption (MJ)

- Acidification potential (kg SO₂ eq.)

- Eutrophication potential (kg PO₄³⁻ eq.)

- Tropospheric ozone formation potential (kg C₂H₄ eq.)

Parklex Prodema panels have environmental declarations that recognize the environmental aspects of the products from the design phase, reducing negative impacts throughout their life cycle.

Contribution to Sustainable Building Certifications

Wood finishes can significantly contribute to earning points in major sustainable building certification systems:

- LEED v4: Contribution in Materials and Resources (MR), Indoor Environmental Quality (EQ), and Energy and Atmosphere (EA) categories.

- BREEAM: Favorable scoring in Materials, Health and Wellbeing, and Energy categories.

- VERDE: Contribution in Energy saving and efficiency and Use of renewable materials areas.

- WELL Building Standard: Contribution to Air, Comfort, and Mind concepts.

Specification with sustainability criteria must consider not only the manufacturing stage but also the material’s durability (reducing the need for replacements).

6. Durability and Maintenance

The technical specification of wood finishes must encompass the entire life cycle of the material, with particular attention to durability and maintenance requirements–factors that directly impact the overall cost and sustainability of the adopted solution.

Durability classes according to EN 350

The European standard EN 350 classifies the natural durability of wood against wood-destroying organisms and establishes five durability classes (DC):

- DC 1: Very durable (service life >25 years)

- DC 2: Durable (service life 15–25 years)

- DC 3: Moderately durable (service life 10–15 years)

- DC 4: Slightly durable (service life 5–10 years)

- DC 5: Not durable (service life <5 years)

High-performance panels such as Parklex Prodema’s NATURCLAD-W and NATURCLAD-B exceed these parameters thanks to specific treatments and the stratified composition that protects the natural wood.

Maintenance and Cleaning

One of the fundamental advantages of high-performance natural wood panels is the drastic reduction in maintenance needs. Unlike natural wood, which requires periodic protective treatments, high-tech panels only need basic cleaning operations.

The PVDF anti-graffiti coating facilitates cleaning by preventing dirt from easily adhering to the surface. Maintenance recommendations for these panels include:

- Cleaning with water and diluted household detergents

- Possibility of pressure washing (maximum recommended pressure: 103 bar)

- Use of lint-free cloths or medium-hardness bristle brushes

The use of abrasive products, aggressive solvents such as acetone or nail polish remover, and methods involving external heat sources like hot spatulas or hot air guns should be avoided.

Aging Prediction and Pathology

Resistance to accelerated aging cycles according to standards such as EN ISO 4892-2 allows for predicting the long-term aesthetic and technical performance of the panels. Advanced systems maintain color stability with limited variations (ΔE ≤ 5 according to EN 20105-A02) after prolonged exposure to UV radiation and humidity.

Proper design of construction details (expansion joints, cavity ventilation, drainage) is essential to prevent pathologies such as deformations, moisture stains, or premature deterioration.

7. Acoustics and Thermal Insulation

The acoustic and thermal performance of wood finishes is an increasingly valued aspect in contemporary architecture, focused on wellbeing and energy efficiency.

Acoustic Properties

Natural wood finishes contribute to the acoustic conditioning of spaces in various ways:

- Sound Absorption: Perforated or slotted panels, combined with absorbent materials in the rear cavity, can achieve sound absorption coefficients (αw) of up to 0.75 according to EN ISO 354, classified as Class C under EN ISO 11654. This capability significantly reduces reverberation time in interior spaces, improving speech intelligibility and overall acoustic comfort.

- Airborne Sound Insulation: Ventilated facade systems with wood cladding contribute to the building’s acoustic insulation. According to tests conducted in accordance with EN ISO 10140-2, these systems can improve the base facade insulation by 4 to 8 dB(A), depending on the specific configuration and type of insulation used in the cavity.

- Vibration Reduction: The composite structure of high-performance wood panels provides greater vibration damping compared to homogeneous materials, helping reduce structural vibration transmission.

Thermal Performance

In the thermal domain, wood cladding for ventilated facades offers significant advantages:

- Thermal Resistance: Wood panels exhibit thermal conductivity (λ) around 0.3 W/m·K, significantly lower than materials like aluminum or steel.

- Ventilated Facade Effect: The ventilated facade configuration creates an air cavity that acts as an additional thermal barrier, reducing solar gains in summer and heat losses in winter. Studies show reductions of up to 30% in cooling energy demand in warm climates.

- Thermal Inertia: The specific heat capacity of wood (approximately 1,600 J/kg·K) contributes to the system’s thermal inertia, buffering external temperature fluctuations.

Ventilated facade systems with wood cladding significantly contribute to the overall energy efficiency of the building and can be essential for meeting requirements set by regulations such as Spain’s Technical Building Code (CTE) or international Passivhaus standards.

8. Compatibility with Construction Systems

The effective integration of wood finishes into construction systems requires a detailed analysis of technical compatibilities and specific design considerations. This aspect is particularly relevant during the specification phase, as it largely determines the feasibility and success of execution.

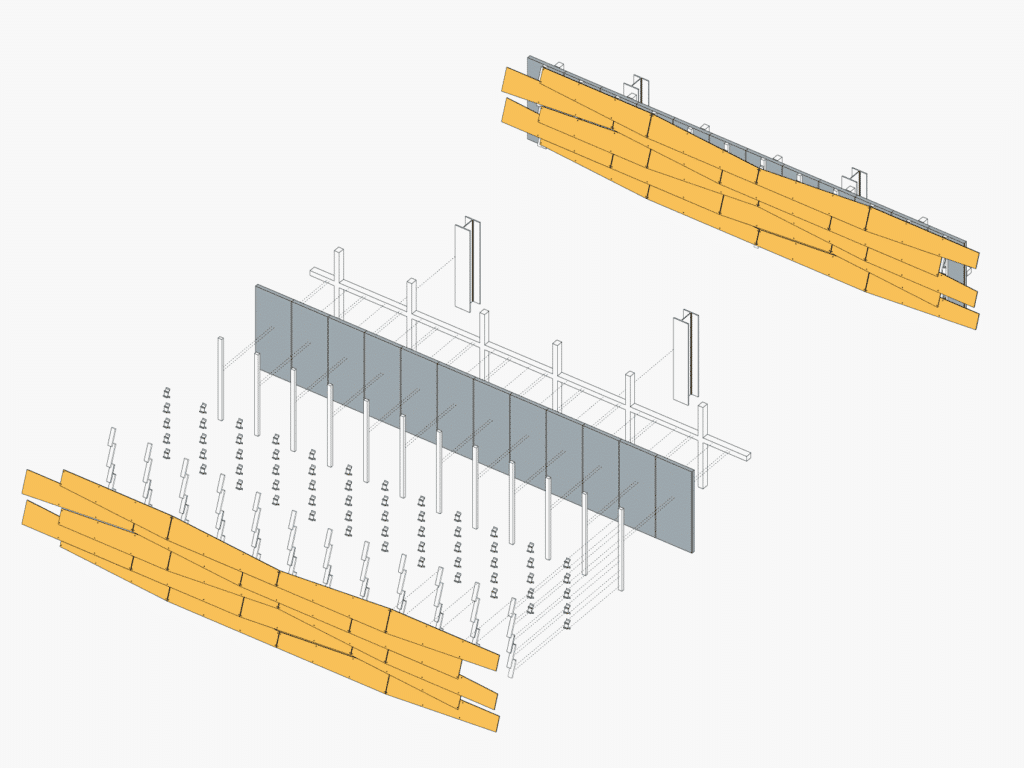

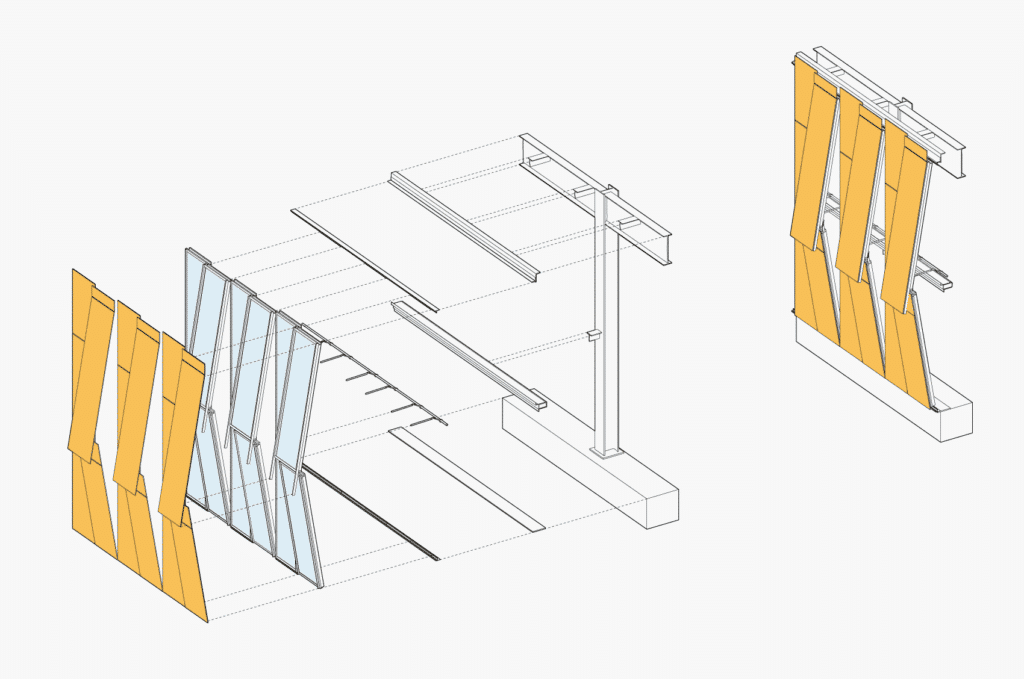

Fastening Systems and Subframe

High-performance wood finishes support various fastening systems, each with specific characteristics:

- Visible Fastening with Screws or Rivets: An economical and simple system that allows individual panel removal for replacement. The spacing between vertical channels for 8–10 mm panels is 600 mm, increasing to 800 mm for 12 mm panels.

- Concealed Fastening with Plugs: Available for 10–12 mm thick panels, it offers a superior aesthetic finish by concealing fastening elements with plugs made of the same material and finish as the panel.

- Concealed Fastening with Hooks: A system that allows installation of 8, 10, and 12 mm thick panels without visible perforations, also facilitating more complex facade layouts and eventual panel replacement.

- Concealed Fastening with Adhesive: For 8, 10, and 12 mm panels, using certified structural adhesives. It requires reduced spacing between channels (400 mm for 8 mm panels, 600 mm for 10–12 mm) to ensure proper polymerisation.

Compatibility with Insulation and Barriers

The specification of wood finishes must consider the interaction of the wood finish system with other construction elements:

- Insulation: Compatibility with mineral wool, extruded polystyrene, polyurethane, and other insulating materials

- Vapor Barriers: Integration with waterproof and breathable membranes

- Watertightness: Solutions to ensure water tightness at singular points

Solutions for Singular Points

The proper resolution of singular points largely determines the technical and aesthetic success of the finish:

- Corners: Options for mitred, overlapped, or specific channel corners

- Window Openings: Details for sills, lintels, and jambs

- Top Termination: Systems for proper protection and upper ventilation

- Facade Base: Solutions for lower ventilation and splash protection

Specialized manufacturers like Parklex Prodema provide detailed technical documentation for the correct execution of these points, adapting to various construction typologies and specific project requirements.

Harry Parker Community Boathouse, Anmahian Winton Architects

9. Technical Documentation for Professional Specification

The correct specification of wood finishes requires access to and understanding of specific technical documentation that supports project decisions and ensures regulatory compliance.

Mandatory Documentation

CE Marking: Required for construction products marketed in the European Economic Area under the Construction Products Regulation (EU) 305/2011. For facade cladding, CE marking is based on the harmonized standard EN 438-7 or a European Technical Assessment (ETA).

Declaration of Performance (DoP): Document accompanying the CE marking in which the manufacturer declares the product’s performance with respect to its essential characteristics:

- Fire reaction

- Flexural strength

- Impact resistance

- Durability

- Content and/or release of dangerous substances

Safety Data Sheet: Document providing information on potential material hazards and safe handling recommendations, mandatory under the REACH Regulation.

Supplementary technical documentation

Product Data Sheets: Documents detailing the physical, dimensional, and performance characteristics of the cladding, including tolerances, available finishes, mechanical properties, and behavior against external agents.

Technical Suitability Documents (DIT or DAU): Favorable technical assessments conducted by authorized bodies that validate the suitability of innovative construction systems:

- DIT Plus (Spain)

- ATT (France)

- Zulassung (Germany)

- CCRR (United States)

- Agrément Certificate (United Kingdom)

Catalogs of Construction Details: Collections of technical solutions for various junctions and construction situations, essential for proper wood finish integration into the building.

Digital Tools for Specification of Wood Finishes

BIM Libraries: Parametric digital files that enable integration of wood finishes into BIM models, facilitating interdisciplinary coordination and interference detection.

Facade Configurators: Interactive tools that allow visualization of finish combinations, panel layouts, and fastening systems, aiding aesthetic and technical decision-making.

Digital Specification Platforms: Systems that integrate technical documentation in formats compatible with architectural specification software suites.

The availability of complete and up-to-date technical documentation not only facilitates proper specification but also serves as a distinguishing factor among manufacturers, indicating commitment to quality and technical support for designers.

10. Frequently Asked Questions

What is the main difference between a natural wood panel and a high-performance natural wood panel for exterior cladding?

High-performance panels like NATURCLAD combine natural wood veneers with a core of fibers treated with thermosetting resins, subjected to high pressure and temperature. They also incorporate UV- and weather-resistant PVDF coatings. This structure provides dimensional stability, mechanical strength, and durability far superior to natural wood, eliminating the need for periodic maintenance.

What panel thickness is recommended for ventilated facades?

Ideal thicknesses for exterior facades are 8 mm or 10 mm. Greater thickness allows for wider spacing between subframe channels: 600 mm for 8–10 mm panels and 800 mm for 12 mm panels. The choice depends on the specific design and structural requirements of the project.

How does facade orientation affect the durability of wood cladding?

Orientation significantly influences exposure to UV radiation and rain. South- and west-facing facades (in the northern hemisphere) receive more solar radiation, while those facing prevailing winds experience greater rain impact. Modern natural wood panels maintain performance in any orientation, though manufacturers often reduce the warranty period when the installation angle exceeds 30° from the vertical due to increased solar incidence and potential water accumulation.

Can wood cladding be used in high-rise buildings with strict fire protection requirements?

Yes, specific solutions like Parklex Prodema’s GRCLAD panels incorporate a fiberglass-reinforced core that makes them non-combustible. These panels achieve B-s1,d0 and A2-s1,d0 classifications under EN 13501-1 and comply with standards such as NFPA 285, allowing use in high-rise buildings under the most stringent regulations.

What advantages does a ventilated facade with wood cladding offer over other construction systems?

Key advantages include: permeability (diffusion of water vapor from interior to exterior), water protection (prevents infiltration into the building), thermal insulation (eliminates thermal bridges), solar protection (improves indoor thermal comfort by reducing summer overheating), and acoustic protection (acts as a barrier to sound waves). Additionally, wood provides aesthetic warmth and biophilic benefits that other materials cannot offer.

Is any special treatment required for panel edges after cutting?

No, high-performance wood panels like NATURCLAD require no additional finishing or protection after cutting. Rough edges can be smoothed with sandpaper if needed, but no specific sealing or varnishing is required.

What spacing should be left between panels for expansion joints?

Expansion joints must be left around the perimeter of all panels to allow for movement due to expansion. Joint thickness depends on panel dimensions and facade design, but as an example, for 2440×1220 mm panels, joints should be at least 6–8 mm. Sealing joints with flexible materials is not recommended to avoid dirt accumulation on edges.