TABLE OF CONTENTS

- 1. Introduction: Functionality and Aesthetics in Natural Wood Flooring for Interiors

- 2. The Technical Evolution of Natural Wood Flooring

- 3. Advanced Technical Features of Contemporary Natural Wood Flooring

- 4. The Relationship Between Durability and Aesthetics in Natural Wood Flooring

- 5. Architectural Applications: High-Traffic Environments

- 6. Solutions for Spaces Exposed to Moisture

- 7. Sustainability and Life Cycle of High-Performance Wood Flooring

- 8. Integration with Radiant Heating Systems

- 9. Compliance with International Technical Standards

- 10. Frequently Asked Questions About Natural Wood Flooring for Interiors

1. Introduction: functionality and aesthetics in natural wood flooring for interiors

Natural wood flooring for interior applications represents the ideal convergence of architectural functionality and aesthetic warmth. Traditionally considered delicate and high-maintenance, this material has undergone a significant technical transformation in recent decades. Advances in treatment and composition technologies have overcome the historical limitations associated with wood as a flooring material.

The technical evolution of wood flooring has preserved the material’s inherent expressiveness and warmth while incorporating durability characteristics previously exclusive to synthetic materials. This transformation directly addresses the demands of contemporary architectural spaces, where intensive use and maintenance requirements call for high-performance solutions without compromising aesthetic quality.

The development of high-performance natural wood flooring emerged as a response to an architectural market that values both the material’s authenticity and its long-term performance. A pivotal moment in this evolution was the development for the Guggenheim Museum in Bilbao in 1997, where the challenge was to create a floor that maintained the natural aesthetics of wood while withstanding the foot traffic of over 1.3 million visitors annually. This specific application spurred a new generation of high-performance flooring capable of enduring extreme conditions without compromising material expressiveness.

2. The technical evolution of natural wood flooring

Natural wood flooring has undergone a radical transformation through the implementation of technologies that combine traditional woodworking methods with innovations in composites and surface treatments. The evolution of these floors can be understood in three key phases:

(1) Traditional Solid Wood Flooring: These required intensive maintenance and were highly sensitive to hygrothermal changes. While aesthetically highly valued, these floors had significant limitations in terms of dimensional stability and wear resistance.

(2) Second-Generation Multilayer Flooring: These introduced multilayer structures that significantly improved dimensional stability. However, the top layer remained vulnerable to wear, requiring periodic maintenance through sanding and refinishing.

(3) Third-Generation Hybrid Technologies: The current generation combines natural wood with advanced protection systems. This approach preserves the expressiveness of natural wood while incorporating previously unattainable technical performance for organic materials:

- Superior Dimensional Stability: Achieved through balanced structures that minimize the natural movement of wood.

- Wear Resistance: Implementation of surface treatments that protect the wood without concealing its natural texture.

- Reduced Maintenance: Elimination of refinishing cycles through integrated protection systems during manufacturing.

This technical evolution has significantly expanded the applications of natural wood flooring, including environments where its use was traditionally ruled out due to its limitations. Products like Parklex Prodema’s NATURFLOOR-W floors represent this stage of evolution, combining veneers of species such as oak, walnut, or ash–incorporating advanced technology–with highly stable birch plywood cores and advanced surface treatments that ensure performance even in extreme conditions.

3. Advanced technical features of contemporary natural wood flooring

Contemporary natural wood flooring incorporates technical characteristics that radically distinguish it from its predecessors, transforming its performance and application capabilities. Key features include:

Abrasion and wear resistance

Current systems achieve AC6 ratings under the European standard UNE-EN 13329, the highest category, ensuring suitability for extremely high-traffic environments such as airports or shopping centers. This classification is obtained through accelerated wear tests simulating decades of intensive use.

Scratch resistance

The implementation of protective layers specifically developed for natural wood achieves Grade 4 ratings under standards like European EN 438. This level ensures the floors maintain their aesthetic integrity even in high-risk situations, such as occasional furniture dragging or foot traffic with abrasive footwear.

Dimensional stability

Multilayer structures drastically reduce the natural movement of wood. While traditional solid wood flooring can experience dimensional variations of up to 8% with seasonal hygrothermal changes, advanced systems limit these movements to less than 0.1%, eliminating issues such as warping, cupping, or gaps between planks.

Moisture resistance treatment

New generations incorporate treatments that alter the wood’s natural hydrophilic structure, enabling its use in environments with occasional moisture, such as bathrooms or kitchens. These treatments are not mere surface varnishes but structural modifications that maintain vapor permeability while repelling liquid water.

Thermal resistance

Advanced systems offer optimized thermal resistance values (typically between 0.07 and 0.15 m²K/W), allowing efficient integration with radiant heating systems without compromising the overall energy efficiency.

Fire ferformance

The most technically advanced versions incorporate flame-retardant treatments that achieve Bfl-s1 classifications under the European system, meeting safety requirements for public buildings and marking a critical difference from traditional wood flooring.

These characteristics are achieved through manufacturing processes that preserve the visual and tactile nature of wood while radically transforming its physical properties, creating a hybrid material where the natural and the technical converge.

4. The relationship between durability and aesthetics in natural wood flooring

The balanced integration of technical durability and aesthetic expressiveness is the primary challenge in developing advanced natural wood flooring. Historically considered inversely proportional, this relationship has evolved significantly thanks to technologies that protect the wood without compromising its natural appearance.

The technical enhancement of natural wood surfaces is achieved through complementary strategies that preserve and enhance the material’s visual and tactile qualities.

Strategies to enhance visual and tactile qualities

Contemporary surface treatments maintain controlled micro-roughness that preserves the characteristic tactile sensation of wood, avoiding the artificial appearance and plastic feel of traditional protective systems. This micro-texture also allows light to interact naturally with the surface, preserving the visual depth typical of wood.

Current technology enables the use of low-gloss finishes (between 3 and 7 units on the reflectance scale) that maintain the natural matte appearance of wood without compromising the physical properties of the protective layer. This factor is particularly relevant in high-quality architectural applications, where artificial gloss is perceived as an undesirable aesthetic distortion.

Protective systems are designed to allow the natural breathing of wood, preserving its hydrodynamic exchange with the environment. This characteristic is essential for maintaining the “living material” sensation that distinguishes natural wood from its artificial imitations.

The selection of natural veneers incorporates knots, tone variations, and characteristic grain patterns of each species, elements traditionally considered “imperfections” but now valued as expressions of material authenticity. In products like those from Parklex Prodema, these variations are deliberately preserved in finishes such as “Rustic Oak” or “Country Oak,” enhancing the natural expressiveness of the wood through technologies that highlight these characteristics without compromising overall durability.

The articulation between technical durability and material expressiveness is also achieved through perimeter beveling of the planks, a technique that emphasizes the individuality of each piece while facilitating the technical resolution of joints. This construction detail can be selectively applied along the longitudinal edges or the entire perimeter of the pieces, depending on the expressive needs of the architectural project.

5. Architectural applications: high-traffic environments

Natural wood flooring reaches its fullest expression in high-traffic architectural applications, where extreme functional demands coexist with the need for the visual and tactile warmth of natural materials. Notable applications include:

Cultural and museum spaces

Environments that combine intense foot traffic with high aesthetic demands. The Guggenheim Museum in Bilbao is a paradigmatic case, where natural wood flooring has demonstrated its durability by withstanding over 25 million visitors since its opening without requiring replacement. The Museum of Pilgrimages and Santiago, designed by Manuel Gallego, also exemplifies this application, using beech wood flooring that, in line with Galician tradition, adds warmth to a space defined by stone materials.

Contemporary corporate environments

Current trends in office design aim to humanize workspaces through natural materials. Projects like the NIDA offices, designed by RAAM Architecture, integrate high-performance natural wood flooring in American oak tones to differentiate functional areas while maintaining a cohesive material language. These applications are particularly demanding due to the use of wheeled chairs and constant equipment movement.

Hospitality and dining spaces

Settings where aesthetic expressiveness is as crucial as resistance to intense traffic and potentially aggressive agents. The Kimpton Vividora Hotel in Barcelona, developed by El Equipo Creativo, uses high-performance American oak flooring to define different spaces while ensuring durability against the wear typical of these environments.

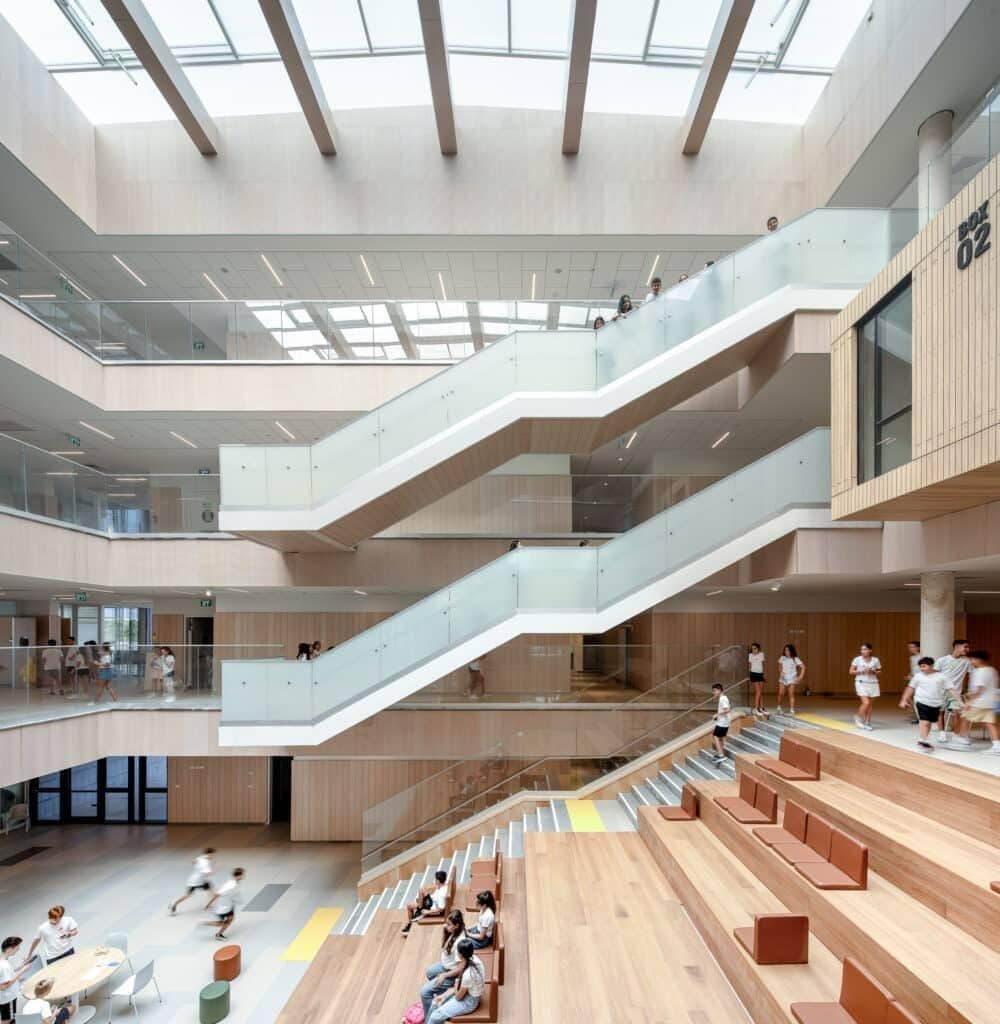

Educational spaces

Highly intensive use environments where durability and ease of maintenance are priorities. The Naomi Shemer Primary School, designed by Regavim+Architects, implements American oak flooring specifically chosen for its resistance to wear in high-traffic areas used by children.

Healthcare spaces

Environments with specific hygiene requirements where wood was traditionally avoided. The Sant Joan de Déu Pediatric Cancer Center, designed by PINEARQ, incorporates bamboo flooring that combines the psychologically positive effect of natural wood with the hygiene needs of a hospital setting.

In all these applications, the technical performance of advanced natural wood flooring enables its use in conditions that would be impractical for traditional wood, while providing sensory qualities that synthetic materials cannot replicate.

6. Solutions for spaces exposed to moisture

The compatibility of natural wood flooring with spaces exposed to occasional water represents one of the most significant advancements in this field. Contemporary moisture-resistant treatments transform the natural hydrophilic behavior of wood, enabling its use in environments traditionally unsuitable for this material, such as bathrooms, kitchens, or areas with direct access from the exterior.

These systems go beyond traditional varnishes, which merely created a surface barrier easily compromised by small cracks or natural wear. Current technologies modify the wood’s structure through deep impregnation with compounds that alter its hygroscopic behavior without compromising its organic nature.

For example, the moisture-resistant treatment applied to Parklex Prodema’s NATURFLOOR-W flooring allows any of its finishes to be installed in areas with frequent water contact, while maintaining high resistance to stains from substances such as bleach, ammonia, nail polish, coffee, or wine.

Other applications of natural wood flooring

This resistance does not imply complete waterproofing of the flooring but rather a controlled behavior that prevents rapid water absorption while maintaining the vapor exchange necessary for the material’s hygrothermal balance. Technically, this enables the use of natural wood flooring in:

- Lobbies and direct entry areas from the exterior

- Full bathrooms, including areas around showers

- Domestic and professional kitchens

- Dining areas with frequent cleaning

- Locker rooms in sports facilities

Complementary moisture protection

Moisture-resistant technology is complemented by floating installation systems that incorporate vapor barriers on the underside, creating comprehensive systems that protect the wood from both surface moisture and potential rising damp from the substrate. This integrated protection eliminates traditional issues associated with using wood in humid environments, such as warping, swelling, or biological deterioration.

It is important to note that this moisture resistance does not make these floors suitable for permanent immersion or unprotected outdoor installation, maintaining a clear distinction between products specifically developed for interiors and those designed to withstand outdoor conditions.

7. Sustainability and life cycle of high-performance wood flooring

The sustainability of high-performance natural wood flooring is a decisive factor in its selection for contemporary architectural projects. This sustainability must be evaluated across the entire product life cycle, from raw material sourcing to potential reuse or recycling.

Wood sourcing

The wood used in high-quality flooring primarily comes from forests managed under PEFC or FSC certifications, ensuring that extraction does not compromise the viability of forest ecosystems. Species such as oak, walnut, maple, or ash used by manufacturers like Parklex Prodema are sourced from forest management processes that guarantee long-term resource renewal.

Manufacturing efficiency

Manufacturing using High Pressure Laminate (HPL) technology optimizes wood resource use by employing thin veneers (typically 0.6 to 1 mm) for the visible layer. This material efficiency contrasts with traditional solid wood floors, where the use of noble wood is significantly less efficient.

Operational lifespan

The dimensional stability and wear resistance of high-performance flooring significantly extend its operational lifespan. While traditional wood floors require renewal cycles every 7–10 years, contemporary floors maintain their performance for over 20–25 years, even under intensive use conditions. This longevity substantially reduces the environmental impact associated with floor replacement and renovation.

Maintenance-Free

The minimal maintenance requirements eliminate the energy consumption and chemical use associated with periodic sanding and refinishing cycles required by traditional floors. Additionally, routine cleaning can be done with water and neutral detergents, avoiding specialized products with high environmental impact.

Sustainability certifications

Various manufacturers provide Environmental Product Declarations (EPDs under ISO 14025) that objectively quantify the environmental impact across the product’s life cycle. These documents enable precise integration of these materials into projects seeking sustainability certifications such as LEED, BREEAM, or VERDE.

8. Integration with radiant heating systems

The compatibility of high-performance natural wood flooring with radiant heating systems is a technically significant aspect in contemporary architecture. This integration combines the aesthetic warmth of wood with the energy efficiency and thermal comfort provided by radiant heating.

Contemporary natural wood floors have optimized thermal resistance values, typically between 0.07 and 0.15 m²K/W, significantly lower than those of traditional solid wood. This reduction is achieved through multilayer structures with high-density cores that enhance thermal transmission while maintaining overall dimensional stability.

Improved thermal conductivity enables efficient heat transfer from radiant circuits to the floor surface, reducing system energy consumption and response times. While traditional solid wood floors require high flow temperatures (>45°C) to achieve comfortable surface temperatures, technical systems can operate efficiently with moderate flow temperatures (35–40°C).

The superior dimensional stability of these advanced floors is particularly important when combined with radiant systems. Minimized contractions and expansions (<0.1%) prevent gaps between planks during heating and cooling cycles, a common issue with traditional solid wood installations.

The characteristic floating installation of many technical flooring systems creates an air chamber between the floor and radiant circuits, optimizing thermal distribution and reducing hot spots. This chamber also serves as a dilation space that absorbs minimal dimensional movements of the material.

Parklex Prodema’s NATURFLOOR-W flooring is suitable for installation over radiant heating. These floors can reduce thermal resistance, approaching the performance of ceramic floors while retaining the sensory qualities of natural wood.

Recommended heating and cooling protocols for these integrated installations are less restrictive than those required for traditional floors.

9. Compliance with international technical standards

Natural wood flooring has evolved to meet the most stringent international regulatory standards, facilitating its specification in architecturally complex projects. This regulatory compliance covers multiple aspects:

Durability

In terms of wear resistance and durability, products like NATURFLOOR-W achieve an AC6 rating under the European standard UNE-EN 13329, the highest category for abrasion resistance. This classification ensures suitability for the most demanding commercial applications per international standards for laminated flooring.

Fire safety

Regarding fire safety, advanced floors can achieve Bfl-s1 ratings under EN 13501-1, meeting building code requirements laid down for evacuation routes and public spaces. This classification, combining limited fire contribution (B) with low smoke production (s1), is exceptional for an organic material like wood.

Slip resistance

In terms of slip resistance, these floors comply with international standards such as Spain’s DB-SUA from the Technical Building Code, which sets safety requirements to prevent falls. Depending on the specific surface finish, they can achieve ratings from Class 1 to Class 3 under pendulum testing, adapting to the requirements of different architectural spaces.

Volatile organic compounds (VOCs)

Regarding VOC emissions, advanced systems comply with regulations like France’s Émissions dans l’air intérieur, achieving A+ ratings that ensure their contribution to indoor air quality. These certifications are particularly relevant for projects seeking healthy building accreditations like WELL or RESET.

Accessibility

In terms of accessibility, these floors meet international standards for walkability and resistance, making them compatible with wheelchair use and other mobility aids. Their uniform surface and resistance to indentation ensure maintained performance under concentrated loads typical in these contexts.

International standards

Manufacturers provide documentation certifying the suitability of these systems for various construction contexts, facilitating their specification in projects where technical verification is critical. In this regard, Parklex Prodema meets the technical criteria established by international building institutes, including DIT Plus (Spain), ATT (France), Zulassung (Germany), ETA (Europe), CCRR (USA), and Agrément Certificate (UK).

Sustainability

As previously noted, regulatory compliance extends to sustainability, with Environmental Product Declarations (EPDs under ISO 14025) certifications enabling integration into buildings pursuing sustainability certifications like LEED, BREEAM, or VERDE.

10. Frequently asked questions about natural wood flooring for interiors

What distinguishes high-performance natural wood flooring from traditional wood flooring?

High-performance natural wood flooring primarily differs due to its multilayer structure with high-density cores, advanced surface treatments, and integrated protection systems during manufacturing. While traditional flooring requires periodic maintenance through sanding and varnishing, high-performance flooring retains its characteristics throughout its lifespan without these processes. Additionally, it offers superior dimensional stability, improved wear resistance, and compatibility with humid environments.

Is it possible to install natural wood flooring in bathrooms and kitchens?

Yes, natural wood flooring with moisture-resistant treatments can be installed in bathrooms and kitchens where occasional water contact occurs. These treatments modify the wood’s natural hydrophilic behavior, allowing its use in these environments without the traditional issues of warping, swelling, or biological deterioration associated with wood in humid areas. However, they are not suitable for permanent water immersion or outdoor installation.

What maintenance do high-performance natural wood floors require?

The maintenance of high-performance natural wood flooring varies by manufacturer. For maintenance-free floors, such as Parklex Prodema wood flooring, regular cleaning with water and neutral detergents is sufficient. Generally, they do not require the periodic sanding and varnishing typical of traditional flooring. For stubborn stains, specific products recommended by the manufacturer can be used. It’s important to avoid abrasive cleaners or those with strong solvents that could damage the protective layer.

Are natural wood floors compatible with underfloor heating systems?

Yes, contemporary natural wood flooring is fully compatible with underfloor heating systems. They feature optimized thermal resistance values (typically between 0.07 and 0.15 m²K/W), allowing efficient heat transmission. Their superior dimensional stability prevents gaps between planks during heating and cooling cycles. Some manufacturers develop versions specifically optimized for this application with even lower thermal resistance.

What wear resistance rating do high-performance natural wood floors achieve?

Advanced natural wood flooring can achieve an AC6 rating according to the European standard UNE-EN 13329, the highest category on the abrasion resistance scale. This rating, obtained through accelerated wear tests, ensures suitability for the most demanding commercial applications, including airports, hotels, and shopping centers with extremely high foot traffic.

Are natural wood floors sustainable?

High-performance natural wood flooring has a favorable sustainability profile when considering its entire lifecycle. The wood used primarily comes from forests managed under PEFC or FSC certifications. Manufacturing technology optimizes wood resource use through minimal-thickness veneers. Their durability and low maintenance reduce the environmental impact associated with replacement and renovation. At the end of their lifespan, they can be recycled or used for energy recovery through thermal valorization.

What aesthetic differences exist between various types of natural wood flooring?

Aesthetic differences between types of natural wood flooring are mainly based on the wood species used, the cutting method, color treatments, and surface finishes. Species such as oak, walnut, maple, or ash have distinctive visual characteristics in terms of grain, tone, and presence of knots. Finishes can range from highly uniform surfaces to those that deliberately emphasize the wood’s natural characteristics through finishes like “Rustic” or “Country.” Additionally, beveled edges on planks and installation patterns (straight, herringbone, etc.) contribute to significant aesthetic variations.