TABLE OF CONTENTS

- 1. Introduction to Interior Wood Paneling

- 2. Technological Evolution of Natural Wood Panels

- 3. Wood Flooring for High-Traffic Spaces

- 4. Vertical Wood Paneling and Ceilings

- 5. Applications in Wet Spaces and Special Interiors

- 6. Biophilic Design and Connection with Nature

- 7. Technical Aspects for Professional Specification

- 8. Maintenance and Long-Term Durability

- 9. Frequently Asked Questions about Interior Wood Paneling

1. Introduction to interior wood paneling

Natural wood has been a cornerstone of architectural design throughout the history of construction, providing warmth, comfort, and an intrinsic connection to nature. In contemporary architecture, interior wood paneling has undergone a significant transformation, blending the aesthetic nobility of this material with technological advancements that enhance its physical properties, resistance, and durability.

Unlike traditional solid wood, modern natural wood panels offer solutions tailored to the demands of today’s interior architecture: greater dimensional stability, superior mechanical strength, predictable performance under temperature and humidity variations, and minimal to no maintenance requirements. These characteristics have positioned high-performance wood paneling as versatile solutions adaptable to high-traffic spaces such as airports, museums, hospitals, and commercial environments, where technical performance is as crucial as aesthetics.

Natural wood panels represent the evolution of a traditional material into high-performance contemporary solutions, allowing architects to leverage the sensory and aesthetic qualities of wood without compromising technical requirements or worrying about the unpredictable behavior typical of untreated natural materials.

2. Technological evolution of natural wood panels

The development of wood panels has followed a path of constant innovation since the introduction of the first plywood boards in the early 20th century. The most significant advancement came with the introduction of high-density panels (HPL, High Pressure Laminate) featuring natural wood surfaces. This technology combines a core of resin-treated fibers compressed at high temperature and pressure, overlaid with natural wood veneers protected by technical coatings resistant to UV radiation, abrasion, and chemical agents.

This multilayer structure represents a fundamental advancement over conventional panels because it:

- Preserves the natural aesthetic and texture of real wood on the surface

- Ensures dimensional stability under varying environmental conditions

- Offers superior resistance to abrasion, impact, and scratching compared to untreated wood

- Eliminates the need for periodic treatments such as varnishes or oils

- Guarantees predictable and uniform performance across the entire surface

The manufacturing process for these panels involves controlled procedures, starting with the selection of wood species from sustainably managed forests. The veneers undergo treatments to enhance their stability and durability, and are then bonded to a birch plywood core. The result is a panel that retains the visual and tactile naturalness of wood but with enhanced technical properties.

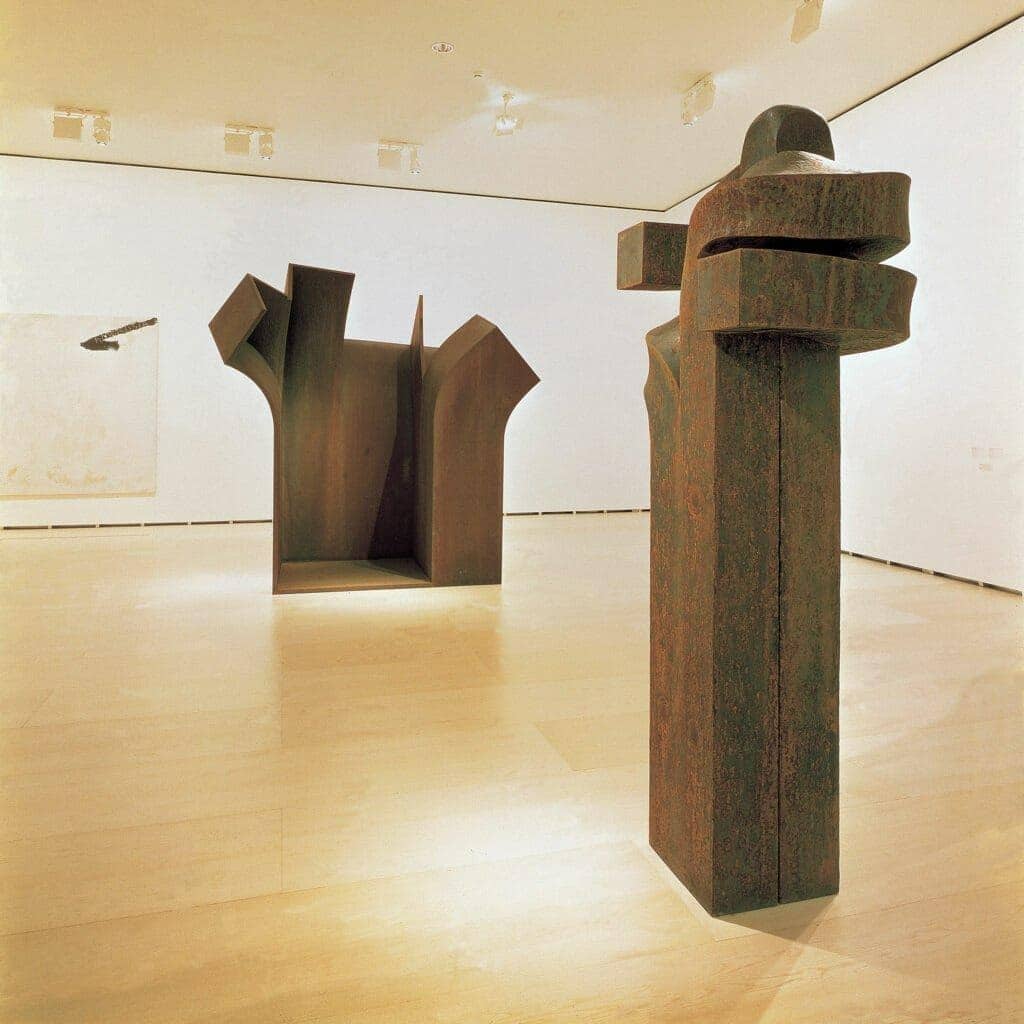

Examples of this technological evolution include the NATURFLOOR-W and NATURPANEL-W panels from Parklex Prodema, which integrate natural wood veneers onto a plywood core. Originally developed for exterior applications, this technology was adapted for interiors when projects like the Guggenheim Museum in Bilbao (1997) required flooring with the warmth of wood but capable of withstanding over 1.3 million annual visitors, demonstrating the viability of these materials in high-traffic environments.

3. Wood flooring for high-traffic spaces

Natural wood flooring represents an architectural solution for spaces requiring both aesthetic qualities and exceptional wear resistance. Unlike traditional solid wood floors or conventional laminates, these systems press wood veneers at high pressure and temperature, combining them with resin overlays that provide the wood with enhanced hardness. Finally, the veneers are bonded to a birch plywood substrate, which delivers superior stability and durability.

The demand for these floors has grown significantly in public and commercial spaces due to their technical performance, which allows them to maintain the appearance and texture of natural wood without the drawbacks associated with intensive maintenance or susceptibility to deterioration.

3.1. Installation systems and dimensions

Natural wood flooring is available in various formats and installation systems tailored to specific architectural needs:

Standard Dimensions: Standard Dimensions: Planks are typically offered in lengths of 2440 mm with variable widths (188 mm, 290 mm, and 590 mm), allowing for different laying patterns. For special installations such as herringbone patterns, specific formats of 188×1200 mm are available. The standard thickness of 14 mm provides stability without adding excessive height to the floor.

Installation Systems: The main systems include:

- Floating with tongue-and-groove joints: Enables quick installation without permanent adhesives, facilitating assembly and ensuring precise joints.

- Direct gluing: Offers greater stability and reduced acoustic transmission.

Laying Patterns: The dimensional versatility allows for multiple configurations:

- Staggered row pattern (1/4 offset)

- Half-bond joints (1/2 offset)

- Traditional or French herringbone

- 45° installation relative to walls

- Compositions with planks of different widths

Beveling of the edges, which can be applied to all four sides or only the longitudinal ones, aesthetically defines the joint between planks and emphasizes the floor’s modularity. In patterns like herringbone, perimeter beveling ensures visual precision at the joints.

3.2. Technical characteristics and resistance

The primary advantage of high-performance natural wood flooring is its exceptional resistance to wear. European standards classify these floors based on various performance parameters:

- Abrasion Resistance: High-end floors achieve an AC6 rating under the UNE-EN 13329 standard, the highest in the European flooring classification system. This category certifies suitability for areas with very high traffic, such as airports or shopping centers.

- Scratch Resistance: A Grade 4 rating (per EN 438) indicates exceptional resistance to scratches and surface marks, making it ideal for areas with furniture movement or intensive use.

- Impact Resistance: Determined by the ability to absorb impacts without permanent deformation, wood floors can achieve IC3 ratings, suitable for intense commercial use.

- Moisture Resistance: Anti-moisture surface treatments allow installation in areas with frequent water exposure, maintaining dimensional stability where traditional wood floors would be unsuitable.

- Stain Resistance: Protective coatings guard against aggressive substances such as bleach, ammonia, cosmetics, or high-staining foods (e.g., coffee, wine) without aesthetic deterioration.

NATURFLOOR-W floors from Parklex Prodema exemplify these technical characteristics, having proven their durability in installations like the Guggenheim Museum in Bilbao, where, after decades and millions of visitors, they maintain their structural and aesthetic integrity without requiring replacement.

4. Vertical wood paneling and ceilings

Natural wood vertical paneling and ceilings are architectural elements that transform any interior space by adding visual warmth, acoustic comfort, and a tactile dimension that other materials can scarcely match. Their technical evolution has overcome traditional limitations of wood, particularly in terms of dimensional stability, fire resistance, and maintenance.

4.1. Architectural solutions for walls

Interior wall panels have diversified into systems that enable varied architectural expressions:

- Modular Panels: With standardized dimensions (typically 2440×1220 mm), these allow efficient installation with visible joints that can be part of the design or minimized depending on the architectural concept.

- Plank Systems: These provide a visual rhythm through linear elements of varying widths (typically between 100 and 300 mm), with the option to incorporate spacing between pieces to enhance acoustic performance or integrate lighting.

- Continuous Panels: For spaces requiring seamless surfaces without visible joints, systems are available that minimize the perception of panel connections.

Fastening methods vary depending on the specific project requirements:

- Concealed Fastening with Clips or Channels: Provides a surface free of visible fastenings.

- Visible Fastening with Screws or Rivets: A more cost-effective system that can be used as an aesthetic feature.

- Structural Adhesive Systems: Enable installations without panel perforation, particularly useful in situations with limited cavity depth, such as renovations.

The integration of these panels with architectural elements like flush doors, integrated cabinets, or operable panels allows for continuous surfaces where functional elements blend seamlessly with the overall paneling.

NATURPANEL-W panels from Parklex Prodema exemplify these capabilities, enabling the cladding of continuous vertical surfaces with the same texture and appearance as flooring, creating architecturally cohesive spaces. This is evident in projects like the OD Barcelona Hotel, where architect Víctor Rahola Aguadé used the Caramel Bamboo finish to create a cohesive interior envelope.

4.2. Ceiling installation systems

High-performance natural wood ceilings present specific challenges due to their horizontal orientation and the frequent need for accessibility to installations. The main systems include:

- Continuous Ceilings: Installed directly onto metal framework or wooden battens, these create seamless surfaces that can incorporate integrated access hatches.

- Removable Systems: Allow regular access to installations through modular panels inserted into visible or concealed framework, combining functionality and aesthetics.

- Plank Ceilings: Composed of linear elements with spacing between pieces.

For spaces with specific acoustic requirements, such as auditoriums, conference rooms, or restaurants, these systems can include perforations or grooves that, when combined with acoustic absorbent materials in the plenum, optimize reverberation times and improve speech intelligibility.

Integration of MEP (Mechanical, Electrical, Plumbing) systems can be achieved through:

- Precise perforations for lighting or HVAC elements

- Specialized fastening systems for suspending technical components

- Integrated technical panels that blend into the overall design

Suspended ceilings with NATURPANEL-W or NATURSOFFIT-W panels from Parklex Prodema demonstrate these capabilities in projects like the Arkoslight offices designed by Francesc Rifé Studio, where wood in work areas and the company’s showroom creates a warm atmosphere without compromising acoustic requirements or the integration of complex technical systems.

5. Applications in wet spaces and special interiors

The presence of moisture has traditionally been a limiting factor for the use of wood coverings. However, advancements in surface treatment technology and the composition of high-performance panels have opened new possibilities for their use in wet environments such as bathrooms, kitchens, spas, and indoor pools.

5.1. Anti-moisture surface treatments

Effective protection of natural wood panels against moisture relies on a multilayer approach that combines several factors:

Veneer Treatments: Natural wood veneers undergo stabilization processes that reduce their natural hygroscopicity, limiting dimensional changes due to variations in ambient humidity.

Surface Coatings: Technical coatings are applied to effectively seal the wood surface, creating a barrier against:

- Liquid water absorption (water-repellent effect)

- Surface condensation

- Stains from hygiene products

- Proliferation of microorganisms (fungi, molds)

Stabilized Core: The internal structure of the panels incorporates materials with low moisture absorption, maintaining dimensional stability even in high-humidity conditions.

These treatments preserve the natural appearance and texture of wood while significantly improving its performance in humid conditions. High-performance natural wood panels can withstand frequent splashes and exposure to high ambient humidity without deforming, discoloring, or requiring special maintenance.

The most demanding applications include:

- Vertical coverings in showers and bathroom areas

- Flooring in changing rooms and transition zones in spas

- Suspended ceilings in indoor pools

- Comprehensive coverings in dry saunas (not recommended for wet or steam saunas)

Products like NATURHARDPANEL-W from Parklex Prodema feature a moisture-resistant surface treatment that allows the creation of spaces with the warmth of natural wood in environments where traditionally only ceramic or synthetic materials were used. This can be seen in high-end hotel installations, such as the Hotel Sezz in Saint-Tropez, where wood coverings extend to bathroom areas.

5.2. Applicable regulations and certifications

Wood coverings for wet indoor spaces must comply with specific regulations to ensure their suitability:

- Moisture Resistance: Standards like EN 13329 for flooring classify performance against moisture, with a minimum classification of HC2 recommended for domestic bathrooms and HC3 for commercial wet spaces.

- Slip Resistance: Particularly relevant for flooring in wet areas, classified according to UNE-ENV 12633, with a Class 2 rating (Rd between 35 and 45) recommended for commercial bathrooms or areas with slip risks.

- Hygienic Performance: ISO 846 evaluates resistance to microorganism growth, a critical aspect in wet spaces where fungal and bacterial proliferation must be prevented.

Specific certifications include:

- ETA (European Technical Assessment) for specific applications within the European Economic Area

- VOC Emission Classifications (Volatile Organic Compounds), such as A+ according to French regulations

- Healthy Product Certifications, such as Indoor Advantage Gold

These regulations and certifications provide architects and specifiers with confidence that natural wood coverings will maintain their aesthetic and technical properties even in challenging humidity conditions, significantly expanding the range of possible architectural applications.

6. Biophilic design and connection with nature

Biophilic design, based on humans’ innate affinity with nature, has gained prominence in contemporary architecture as a response to increasingly urbanized and technological environments. Natural wood coverings play a fundamental role in this trend, representing one of the most direct and accessible connections to the natural world within built spaces.

6.1. Psychological and physiological benefits

The incorporation of natural wood in indoor spaces generates measurable positive responses at both psychological and physiological levels:

- Stress Reduction: Studies conducted in hospital, educational, and workplace settings have shown that the visible presence of natural wood reduces cortisol levels (the stress hormone) and blood pressure in occupants. A study from the University of British Columbia found that the presence of visible wood in indoor spaces reduced the activity of the occupants’ sympathetic nervous system from 49.5% to 40.8%, indicating a lower physiological stress response.

- Improved Psychological Well-Being: Exposure to natural materials like wood is associated with positive moods and reduced mental fatigue. This is particularly relevant in spaces where concentration and cognitive performance are critical, such as educational environments or offices.

- Perceived Thermal Comfort: Wood has low thermal conductivity, creating a sensation of warmth both visually and tactilely. Wood coverings can increase the perception of thermal comfort by up to 2°C without altering the actual temperature of the space, contributing to energy efficiency.

- Improved Acoustic Quality: Wood paneling, especially when designed with air chambers or non-uniform surfaces, contribute to a balanced acoustic environment, reducing stress associated with overly reverberant or echo-prone spaces.

These benefits have driven the use of natural wood in environments traditionally dominated by sterile materials, such as hospitals and healthcare centers. The Pediatric Cancer Center at Sant Joan de Déu in Barcelona, designed by PINEARQ, uses NATURFLOOR-W bamboo flooring and antibacterial NATURPANEL-W walls from Parklex Prodema to create a less institutional and more welcoming environment for young patients and their families, demonstrating the practical application of biophilic principles.

6.2. Integration with other natural materials

Natural wood can be effectively integrated with other natural and manufactured materials to create environments aligned with biophilic principles:

- Combination with Natural Stone: The juxtaposition of wood and stone creates tactile and visual contrasts that enrich the sensory experience of the space. The warmth of wood offsets the visual coldness of stone, resulting in balanced environments.

- Integration with Plant Elements: Wood paneling provides a cohesive backdrop for incorporating indoor vegetation, reinforcing the connection with nature. The stability of high-performance panels allows their use in areas with higher humidity associated with plants.

- Interaction with Natural Light: Wood’s ability to reflect light warmly and non-glaringly enhances the benefits of natural lighting. The matte finishes of modern panels prevent unwanted reflections while preserving the characteristic visual depth of wood.

- Complementarity with Technical Materials: Natural wood panels create a positive contrast with technical materials like glass, steel, or concrete, humanizing high-tech spaces such as research centers or corporate buildings.

This integrated approach is evident in projects like the B-Flexion offices, designed by Visnick & Caulfield Associates, where American walnut panels from Parklex Prodema coexist with glass, steel, and textile elements to create a sophisticated corporate environment with the characteristic warmth of natural materials.

7. Technical aspects for professional specification

The proper specification of interior wood paneling requires a deep understanding of its technical characteristics, performance, and long-term behavior. This knowledge enables architects to select the most suitable solution for each specific project.

7.1. Performance combating fire

The fire performance of high-performance wood paneling is evaluated through European (EN) or international (ASTM, NFPA) standards, depending on the applicable jurisdiction:

Reaction to Fire Classification according to EN 13501-1:

- High-performance wood panels can achieve classifications of B-s1,d0 or B-s2,d0 (low flammability, low smoke production, and no dripping of flaming particles).

- This classification allows their use in evacuation routes and high-occupancy public areas with stringent requirements.

Flame Spread Index according to ASTM E84:

- Natural wood paneling can achieve Class A ratings (FSI ≤ 25).

- This classification meets the requirements of the IBC (International Building Code) for virtually all interior applications.

Fire performance is enhanced through:

- Integrated flame-retardant treatments during the manufacturing process

- Specific selection of resins and adhesives in the core

- Multilayer composition with fire-retardant elements

It is important to distinguish between high-performance natural wood panels and traditional solid wood, as the former can achieve significantly better reaction-to-fire classifications due to their composite structure and specific treatments.

7.2. Acoustic insulation

Interior wood paneling contributes to the acoustic quality of spaces in several ways:

- Sound Absorption: Perforated or slotted panels, combined with absorbent materials in the rear cavity, can achieve sound absorption coefficients (αw) between 0.45 and 0.90, depending on the specific design, making them suitable for: (1) auditoriums and conference rooms, (2) restaurants and commercial spaces, and (3) classrooms and educational environments.

- Impact Noise Reduction: In flooring applications, wood floors on elastic substrates can reduce impact noise (ΔLw) by up to 20 dB, significantly improving acoustic comfort between floors.

- Controlled Sound Reflection: Non-perforated wood panels provide reflective surfaces that, when properly designed, contribute to appropriate sound diffusion in spaces where acoustic clarity is important.

Acoustic customization options include:

- Variation in the percentage and pattern of perforations

- Specific design of rear resonator chambers

- Integration with other absorbent elements

7.3. Sustainability and lifecycle

Sustainability aspects are increasingly relevant in architectural specification.

Wood Sourcing

High-quality panels use FSC- or PEFC-certified wood, ensuring its origin from sustainably managed forests. Since 2007, products like those from Parklex Prodema have held FSC® and PEFC certifications, guaranteeing responsible forest management.

Life Cycle Assessment (LCA)

Natural wood paneling exhibits favorable environmental profiles in comprehensive life cycle analyses, with:

- Lower carbon footprint compared to alternative materials (ceramics, synthetics)

- CO₂ storage capacity throughout their service life

- Potential for recyclability or energy recovery at the end of their life cycle

Environmental Product Declarations (EPDs)

Verified documents under ISO 14025 provide quantified environmental impact information, enabling objective comparisons between products.

Contribution to Sustainable Building Certifications:

- LEED: Wood paneling can contribute to categories such as Materials and Resources, Indoor Environmental Quality, and Innovation.

- BREEAM: It contributes to sections like Health and Well-Being, Materials, and Waste.

- VERDE: It impacts areas such as Energy Savings and Efficiency and Use of Renewable Materials.

- WELL Building Standard: It supports concepts like Materials, Mind, and Comfort.

The superior durability of high-performance panels compared to traditional solutions represents an additional sustainability factor, as it extends the product’s service life and reduces the need for frequent replacements.

8. Maintenance and long-term durability

One of the most significant advantages of high-performance natural wood paneling compared to traditional wood is its minimal or nonexistent maintenance and exceptional long-term durability.

Basic maintenance for these systems involves only periodic cleaning with lukewarm water and non-abrasive neutral detergents. Unlike solid wood, they do not require:

- Periodic varnishing

- Oiling or waxing

- Sanding for refinishing

- Treatments against wood-boring insects

This simplicity of maintenance is particularly valuable in commercial installations and public spaces, where downtime for maintenance is typically limited and costly.

The durability of high-traffic natural wood coverings is evident in long-standing installations such as the Guggenheim Museum in Bilbao, where NATURFLOOR-W floors from Parklex Prodema have remained in service for over 25 years, enduring millions of visitors without requiring replacement.

Factors contributing to this exceptional durability include:

- UV Resistance: Surface treatments protect against yellowing or discoloration, maintaining the original appearance even in areas with high sun exposure.

- Dimensional stability: The multilayer structure minimizes movement caused by changes in humidity and temperature, preventing warping, cracking, or joint openings.

- Chemical Resistance: The treated surface resists stains from common household products, including beverages, food, cosmetics, and cleaning agents, which can be easily removed with standard cleaning.

- Mechanical Resistance: The high-density core and the hardness of the treated surface provide exceptional resistance to impacts, abrasion, and daily mechanical wear.

Recommendations to ensure maximum durability:

- Maintain indoor environmental conditions within a relative humidity range of 40-65% and temperatures between 15-27°C.

- Use appropriate protectors (e.g., felt pads) on the legs of movable furniture.

- Implement dirt-trapping systems (e.g., doormats) at entrances from the exterior.

- Perform regular cleaning with damp cloths or mops, avoiding excessive water.

- Avoid using abrasive products or those with high solvent content.

9. Frequently asked questions about interior wood paneling

Does natural wood paneling require periodic varnishing like traditional wood?

No, high-performance natural wood paneling incorporates surface treatments during manufacturing that provide permanent protection. These treatments are significantly more durable and resistant than conventional varnishes applied on-site and are integrated into the panel’s structure. It is neither necessary nor recommended to apply additional varnishes, as they could potentially impair the technical properties of the original surface.

Can wood paneling be used in bathrooms and other wet areas?

Yes, natural wood paneling with specific moisture-resistant treatments is suitable for wet areas such as bathrooms and kitchens. These products are designed to withstand frequent splashes and high-humidity environments. However, they are not recommended for areas with permanent submersion or wet saunas. For bathroom applications, it is essential to select products with appropriate moisture resistance classifications and follow the manufacturer’s installation guidelines to prevent water accumulation.

How does direct sunlight affect high-performance natural wood paneling?

Natural wood paneling incorporates advanced UV protection that minimizes the effects of direct sunlight. Unlike untreated wood, which can experience significant discoloration and surface degradation, these panels maintain their appearance over extended periods, even with direct sun exposure through windows. PVDF (polyvinylidene fluoride) treatments and other specialized coatings act as effective barriers against ultraviolet radiation. However, in areas with extreme and constant sun exposure, slight tonal changes may occur over the long term, though these are significantly less pronounced than with traditional wood products.

What is the difference between natural wood floors and conventional laminate floors?

The primary difference lies in the surface composition: high-performance natural wood floors feature a genuine wood veneer that is visible and tactile, whereas conventional laminates use a printed wood image under a transparent layer. This fundamental difference translates into aesthetic and sensory aspects:

- Natural variation vs. repetitive patterns

- Authentic texture vs. synthetic surface

- Visual depth vs. two-dimensional appearance

- Natural warmth vs. artificial reproduction

Technically, natural wood floors typically offer greater wear resistance (AC5-AC6 ratings compared to AC3-AC4 typical for domestic laminates) and improved acoustic properties.

Is it necessary to acclimate panels before installation?

Yes, it is essential to acclimate high-performance covering panels before installation. Although these products have greater dimensional stability than solid wood, they are still partially natural materials that respond to environmental conditions. It is recommended to store the panels for at least 72 hours in the space where they will be installed, under the final environmental conditions of temperature (15-27°C) and relative humidity (40-65%). For flooring specifically, this acclimation period may extend up to 5 days, as recommended by associations such as the NWFA (National Wood Flooring Association).

What fastening systems are recommended for walls and ceilings?

The choice of fastening system depends on the type of panel, substrate, and aesthetic requirements:

For walls:

- Concealed fastening with clips or channels: Ideal for achieving a surface without visible elements.

- Visible fastening with painted screws or rivets: Provides excellent mechanical strength and can be integrated as an aesthetic element.

- Structural adhesive systems: Suitable when drilling the substrate is not possible or a quick installation is required.

For ceilings:

- Removable systems with visible or hidden framework: Allow access to installations in the plenum.

- Continuous systems on battens: Offer a more integrated appearance when frequent accessibility is not required.

- Suspended planks systems: Combine aesthetics and accessibility.

In both cases, it is essential to follow the manufacturer’s specific recommendations regarding the spacing of fastening points based on the panel thickness.

How does wood paneling contribute to LEED or BREEAM certification?

Natural wood paneling can positively contribute to various categories in sustaina ble building certification systems:

In LEED v4/v4.1 certification:

- Materials and Resources: Use of products with EPDs (Environmental Product Declarations), responsibly sourced materials (FSC/PEFC certifications), and transparency in composition.

- Indoor Environmental Quality: Low emission of volatile organic compounds (VOCs) and contribution to thermal and acoustic comfort.

- Innovation: Specific applications that represent substantial improvements over standard practices.

In BREEAM certification:

- Health and Well-Being: Contribution to indoor environmental quality and occupant comfort.

- Materials: Use of low-impact materials verified through LCA (Life Cycle Assessment).

- Waste: Durable materials that minimize the need for replacements and are potentially recyclable at the end of their life cycle.

The specific contribution value depends on the particular certifications of the selected product, such as EPDs, chain-of-custody certifications (FSC/PEFC), and VOC emission declarations.

What is the expected lifespan of high-performance natural wood paneling?

When properly installed and maintained, the lifespan of these coverings can exceed 25–30 years in high-traffic applications and 40–50 years in residential or moderate-traffic applications. This exceptional durability is evident in installations like the Guggenheim Museum in Bilbao, where Parklex Prodema wood floors have remained in service after more than two decades of intensive use.

Factors influencing longevity include:

- The intensity of use (pedestrian traffic for floors, handling exposure for vertical paneling)

- Environmental conditions (stability of temperature and humidity).

- The quality of the initial installation

- Compliance with cleaning and maintenance recommendations

Many manufacturers offer commercial warranties of 10 years, although the actual lifespan of the product typically far exceeds this period

What options exist for integrating acoustic solutions into wood paneling?

Natural wood paneling offers various possibilities for acoustic optimization:

- Perforated panels with a regular pattern: Circular or square perforations distributed evenly, combined with rear absorbent material, provide sound absorption across a wide range of frequencies.

- Slotted panels: Linear slots with variable width and spacing that combine acoustic functionality with directional aesthetics.

- Micro-perforated systems: Very small perforations (diameter less than 1 mm), nearly invisible, that maintain the continuous appearance of wood while providing absorbent properties.

- Diffuser panels: Three-dimensional relief surfaces that scatter sound waves, improving sound distribution without fully absorbing it.

- Composite systems: Combinations of different zones (absorbent, reflective, diffusive) in a single architectural treatment to optimize acoustic performance based on specific needs.

The acoustic effectiveness of these systems is quantified by the sound absorption coefficient (αw) or NRC (Noise Reduction Coefficient), which can range from 0.45 to 0.90 depending on the specific perforation design and the absorbent material used in the rear cavity.