TABLE OF CONTENTS

- 1. Introduction: The Challenge of Wood in Wet Environments

- 2. Technological Evolution in Protecting Natural Wood

- 3. Technical Properties and Certifications for Wet Environments

- 4. Specific Applications in Bathrooms and Shower Areas

- 5. Solutions for Kitchens: Stain and Moisture Resistance

- 6. Natural Wood in Wellness and Spa Areas

- 7. Installation and Maintenance Considerations in Wet Environments

- 8. Sustainability and Environmental Benefits

- 9. Frequently Asked Questions About Wood in Wet Environments

1. Introduction: The challenge of wood in wet environments

Integrating natural wood finishes in interior spaces, particularly in wet environments, has historically been an architectural challenge due to the material’s inherent vulnerability to moisture. Untreated wood exposed to high humidity tends to undergo dimensional changes, warping, and, eventually, biological deterioration. However, technological advancements in wood treatment and processing have radically transformed the possibilities for using natural wood in wet environments.

The appeal of incorporating natural wood elements in spaces like bathrooms, kitchens, and wellness areas stems from multiple factors: the visual and tactile warmth it provides, its acoustic properties, the psychological connection to natural elements, and its aesthetic versatility. These spaces, traditionally dominated by materials like ceramics, stone, or synthetic surfaces, undergo a significant qualitative transformation when wood is integrated, creating warmer environments with improved thermal comfort.

In the context of contemporary architecture, where there is a growing demand for spaces that combine functionality with sensory well-being, technically treated wood emerges as a material that reconciles seemingly contradictory requirements: naturalness and resilience, warmth and durability, aesthetics and practical functionality.

2. Technological evolution in protecting natural wood

The evolution of wood protection technologies has seen exponential development in recent decades, moving from traditional methods primarily based on surface coatings to advanced techniques that modify the material’s structure.

Traditional vs. advanced protection technologies

Conventional protection methods primarily included:

- Varnishes and lacquers with high moisture resistance

- Treatments with water-repellent impregnating oils

- Application of chemical preservative compounds

While these solutions were temporarily effective, they had significant limitations in terms of durability, frequent maintenance needs, and, in some cases, environmental and health impacts due to the chemicals used.

Current advanced technologies have overcome these constraints through:

- Thermal modification of wood, altering its molecular structure to reduce hygroscopicity

- Vacuum-pressure impregnation with thermosetting resins

- Densification processes for the wood’s fibrous structure

- Hybrid treatments combining physical and chemical modifications

- Development of high-performance multilayer coatings that fully seal the surface

The specific case of natural wood panels for wet environments developed by Parklex Prodema exemplifies this technological evolution. Their manufacturing process incorporates protective layers of thermosetting resins and an outer PVDF (polyvinylidene fluoride) coating, providing exceptional moisture resistance without compromising the natural appearance of the wood surface.

Innovations in composite materials

In parallel, composite material solutions have been developed that maintain the aesthetic of natural wood while incorporating elements that significantly enhance moisture resistance:

- High-density panels with a core of cellulose fibers treated with phenolic resins

- Three-layer coatings with a balancing bottom layer, a high-density core, and a protected natural wood veneer

- Impregnation technologies that evenly distribute protective agents throughout the material’s structure

These innovations have enabled natural wood to be functionally integrated even in areas directly exposed to splashes or frequent water contact, significantly expanding the range of possible architectural applications.

3. Technical properties and certifications for wet environments

The suitability of wood finishes for wet environments is determined by a specific set of technical properties, which must be verified through standardized tests and reflected in corresponding certifications.

Key technical properties

The critical parameters determining wood performance in wet environments include:

- Dimensional stability: Measured as the percentage variation in dimensions due to changes in ambient humidity. High-density natural wood panels treated with thermosetting resins exhibit dimensional variation values below 0.35% longitudinally and 0.65% transversally, significantly lower than untreated wood.

- Water Absorption: Quantified as the percentage weight increase after prolonged water exposure. High-performance wood finishes for wet environments show absorption values below 2% after 24 hours of immersion, compared to untreated wood, which can exceed 15%.

- Moisture Resistance: Evaluated through cycles of exposure to extreme humidity and temperature conditions, assessing changes in physical and mechanical properties. Advanced systems retain over 95% of their properties after these tests.

- Resistance to Biological Attack: The ability to prevent the proliferation of fungi, mold, and bacteria, particularly crucial in environments like bathrooms and kitchens. Modern treatments incorporate antimicrobial properties that inhibit microorganism growth on the surface.

The following table provides values to compare some of these properties:

| Property | Untreated natural wood | High-performance wood |

| Swelling after 24h immersion | 7-15% | <2% |

| Dimensional stability (max variation) | 2-4% | 0.3-0.6% |

| Resistance after web-dry cycles | 25-40% loss | <5% loss |

| Antimicrobial properties | No | Yes |

Relevant standards and certifications

Formal evaluation of these properties is conducted through tests adhering to specific international standards:

- EN 438-2: High-pressure decorative laminates (HPL)

- EN 13329: Laminate floor coverings

- ASTM D2247: Resistance to high humidity

- JIS Z 2801 / ISO 22196: Antibacterial activity on surfaces

- EN 12721: Resistance to humid heat

Certifications specific to wet environments include:

- Moisture resistance classification under EN 13329, achieving levels suitable for commercial wet spaces.

- Certification of VOC (Volatile Organic Compounds) emissions for indoor environments.

- Fire reaction classifications specific to wet-area applications.

The AC6 certification, the highest within the European system for laminate flooring, ensures durability in high-traffic environments even with occasional moisture exposure, such as floors in spas and wellness areas.

4. Specific applications in bathrooms and shower areas

Contemporary bathrooms have evolved toward designs prioritizing sensory experiences and well-being, encouraging the integration of natural materials like wood. This architectural trend involves multiple application variants, each with specific technical requirements.

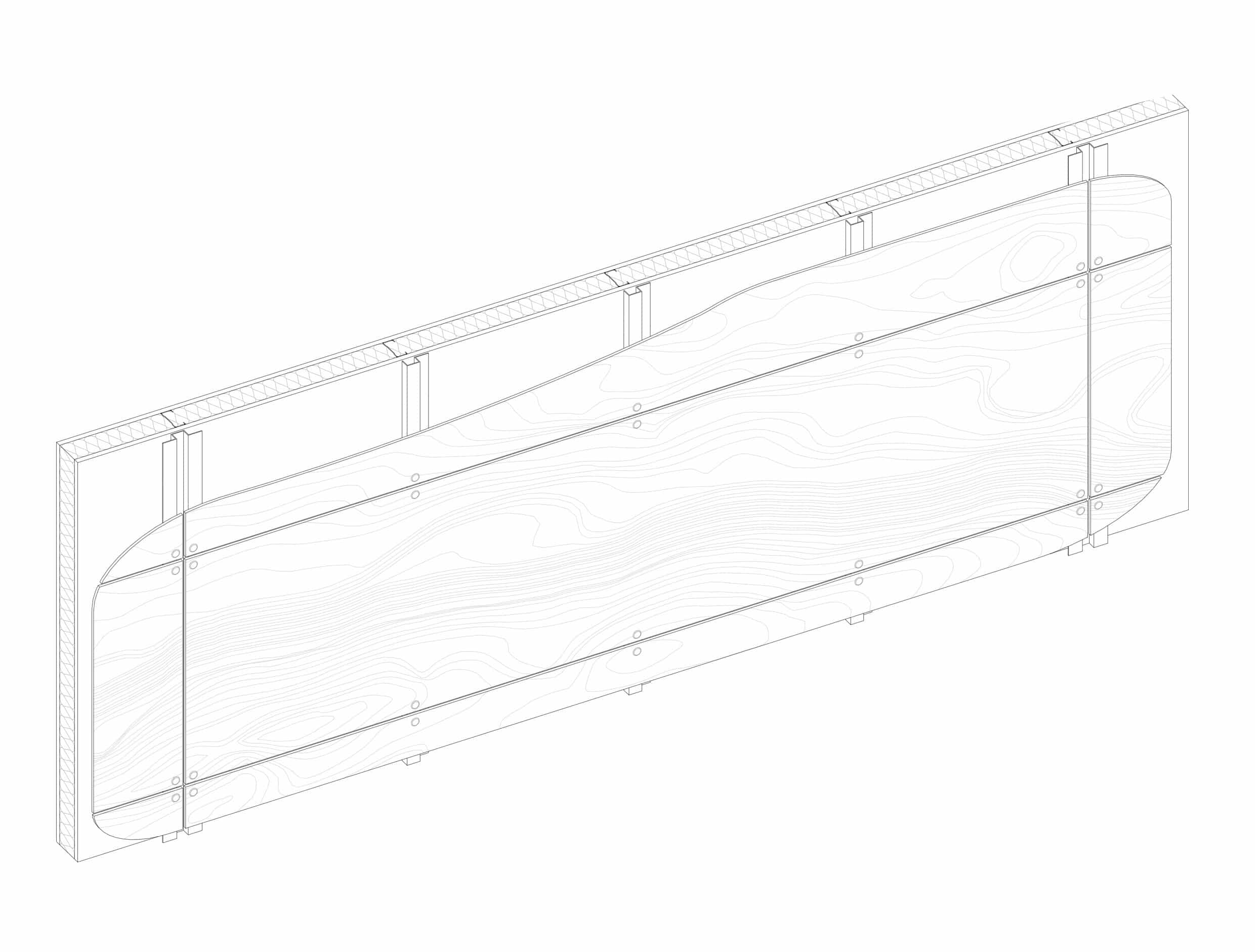

Wall finishes in wet areas

In bathroom areas not directly exposed to running water but subject to high ambient humidity, technically treated natural wood wall finishes offer excellent performance. These panels are characterized by:

- Resistance to ambient humidity fluctuations between 40% and 95% without deformation

- Non-porous surfaces that prevent moisture absorption

- Components that inhibit microbial growth on the surface

Installation of these finishes typically involves:

- A metal or treated wood subframe separated from the wall

- A ventilated air gap to prevent condensation on the back

- Fastening systems that accommodate the material’s natural expansion

- Specific joint treatments to prevent water infiltration

Landaburu Borda Rural House / Kimpton Vividora Hotel

Solutions for shower cabins

In areas with direct water exposure, such as showers and cabins, integrating wood requires advanced technical solutions. Current technology offers two approaches:

Waterproof Integral Panels: Composed of a core of cellulose fibers treated with thermosetting resins and a natural wood surface protected with multiple sealing layers. These panels feature:

- Complete resistance to temporary immersion

- Non-deformable core during prolonged water exposure

- Fully waterproofed surfaces

- Joints sealed with specific elastomeric systems

Coordinated Partial Finishes: Combining treated natural wood in areas with less direct exposure (e.g., side or upper shower zones) with fully waterproof materials in critical areas.

The installation system in these critical zones must ensure:

- Adequate slopes for water drainage

- Complete perimeter sealing at junctions with other materials

- Non-penetrating fastenings to maintain waterproof integrity

- Proper rear ventilation to prevent condensation buildup

Parklex Prodema’s NATURHARDPANEL-W panels, with their high-density core and specific exterior coating, have been successfully implemented in shower cabins in projects such as hotel spas and high-end gym locker rooms, demonstrating their resilience even under extreme exposure conditions.

Natural wood bathroom furniture

Bathroom furniture made from technically treated wood is another increasingly common application. Specific technical considerations include:

- Complete waterproofing of edges and joints

- Corrosion-resistant hardware and fastening systems

- Designs that promote water drainage and prevent accumulation

- Specific treatments for areas with frequent water contact, such as sink surroundings

5. Solutions for kitchens: stain and moisture resistance

In kitchen environments, natural wood must address specific challenges that combine moisture with stringent hygiene and stain resistance requirements.

Specific requirements for kitchen surfaces

Wood finishes for kitchens must meet technical requirements that go beyond simple moisture resistance:

Stain resistance: Stain Resistance: Modern natural wood panels withstand contact with common kitchen agents without alteration, including:

- Weak acids (vinegar, lemon)

- Weak alkalis (detergents, cleaning products)

- Coloring agents (coffee, wine, spices)

- Oils and fats

Antibacterial Properties: Particularly relevant for food preparation and handling surfaces. Advanced treatments incorporate:

- Silver ions in the surface matrix to inhibit bacterial growth

- Non-porous surfaces that prevent microbial penetration and colonization

- Resistance to biofilm formation on the surface

Thermal Resistance: Ability to withstand brief or sustained exposure to elevated temperatures without deformation or surface alterations:

- Resistance to momentary temperatures up to 180°C

- Stability under continuous exposure to 70-80°C

- No VOC emissions even at elevated temperatures

Main applications in kitchen environments

Technically treated wood products find specific applications in various kitchen elements:

Wall Finishes: Particularly in areas between base and wall cabinets, offering aesthetic alternatives to traditional materials like tiles or stainless steel. These finishes require:

- Specific sealing at countertop junctions

- Fastening systems that allow for eventual replacement

- Special treatment in areas near heat sources

Kitchen Furniture: The trend toward warmer, more livable kitchens favors the use of treated natural wood for cabinet fronts and structures. Advanced systems provide:

- Resistance to frequent cleaning without surface degradation

- Stability under exposure to steam and thermal changes

- Superior durability under heavy use

Islands and Work Surfaces: In some designs, work areas with less direct exposure to moisture or heat can incorporate treated natural wood, adding warmth to the ensemble. These applications require:

- Specific sealing of joints and connections

- Surface treatments that facilitate disinfection

- Anchoring systems that accommodate differential movements relative to other materials

6. Natural wood in wellness and spa areas

Wellness and spa areas represent particularly demanding environments for construction materials due to the combination of high humidity, variable temperatures, and, often, the presence of chemical agents like chlorine or mineral salts. However, the warmth and naturalness of wood are especially valuable in these spaces designed for well-being.

Technical characteristics for thermal environments

Wood finishes for wellness spaces require specific performance features:

Resistance to extreme ambient humidity: In spaces like wet saunas or Turkish baths, relative humidity can approach saturation for extended periods. Advanced technical treatments enable natural wood to maintain its integrity in these conditions through:

- Modification of cellular structure to reduce natural hygroscopicity

- Impregnation with resins that seal capillaries and micropores

- Balancing systems to counteract internal stresses

Performance under abrupt thermal changes: Critical in areas with significant thermal contrasts, such as transitions between saunas and rest areas. High-performance natural wood panels maintain dimensional stability through:

- Multilayer structures with compensated behavior

- Treatments that modify the natural thermal expansion coefficient

- Fastening systems that absorb differential movements

Resistance to specific chemical agents: Particularly important in thermal pools or areas with hydrotherapy treatments involving minerals or chemicals. Advanced finishes withstand:

- Exposure to chlorinated or saline water

- Water treatment products with variable pH

- Essential oils and aromatherapy products

Main applications in wellness areas

Specific areas where technically treated natural wood adds distinctive value include:

Perimeter areas of pools and spas: Floor and wall finishes in these zones must combine:

- Slip resistance in wet conditions

- Thermal comfort for barefoot traffic areas

- Durability under occasional exposure to chlorinated or treated water

Dry saunas and thermal areas: Traditionally dominated by natural wood, these applications benefit from technical treatments through:

- Greater durability under extreme wet-dry cycles

- Reduced emission of natural resins at high temperatures

- Improved surface hygiene properties

Rest and transition areas: Spaces that complement direct treatment areas, where wood contributes to creating relaxing atmospheres. These applications particularly value:

- Surface thermal comfort

- Acoustic absorption that promotes calm environments

- Resistance to foot traffic with residual moisture

Parklex Prodema’s NATURSOFFIT-W panels, specifically designed for ceiling and covered horizontal applications, have been successfully implemented in transition areas of large buildings, such as the multipurpose pavilion at the University of Texas Moody Center, demonstrating their ability to withstand high ambient humidity while maintaining aesthetic and structural integrity.

7. Installation and maintenance considerations in wet environments

The long-term effectiveness of natural wood solutions in wet environments fundamentally depends on technically correct installation and maintenance tailored to their specific characteristics.

Installation considerations

Installation requirements vary depending on the application type and level of moisture exposure, but general principles must be observed:

Specific fastening systems: Recommended solutions include:

- Visible mechanical fastening with corrosion-resistant screws or rivets

- Concealed systems using channels or clips that allow differential movements

- Adhesive solutions with products designed for high-humidity conditions

In all cases, the minimum fastening distance recommended by the manufacturer (typically 600 mm for 8-10 mm thick panels and 800 mm for 12 mm panels) must be respected, ensuring sufficient fastening points to prevent deformation.

Joint and junction treatment: Critical points requiring special attention:

- Joints between panels with sufficient width to accommodate expansion (minimum 6-8 mm)

- Perimeter sealing at junctions with other materials using specific silicones

- Specific protection for edges and cuts made on-site

- Top and bottom trims to prevent water infiltration into the subframe

Rear ventilation: Essential for ensuring system durability:

- A ventilated air gap of at least 20 mm between the panel and support

- Properly sized air inlets and outlets to allow circulation

- Appropriately placed vapor barriers to prevent condensation

Maintenance in humid conditions

The maintenance of wood finishes in wet environments benefits from the high level of protection provided by advanced technical treatments, allowing significantly simpler procedures than traditional wood:

Routine cleaning:

- Warm water with non-abrasive neutral detergents

- Avoid products with high chlorine or ammonia concentrations

- Dry afterward to remove residual water from the surface

Handling incidents:

- Persistent stains: Use a manufacturer-recommended specific cleaner

- Surface scratches: Many high-performance panels incorporate protection throughout their thickness, not just on the surface

- Impacts: Replace damaged panels individually, facilitated by removable fastening systems

Preventive maintenance:

- Periodic inspection of joints and seals

- Verification of proper rear ventilation functionality

- Checking the condition of fastenings in high-exposure areas

Unlike traditional wood, high-performance natural wood finishes, such as those from Parklex Prodema, do not require periodic surface renewal treatments (oiling, varnishing) even under moisture exposure, significantly reducing long-term maintenance costs.

8. Sustainability and environmental benefits

The integration of natural wood in wet environments, when achieved through technically appropriate solutions, offers significant environmental benefits that must be evaluated from a complete lifecycle perspective.

Lifecycle analysis

High-performance natural wood panels for wet environments exhibit an environmental profile characterized by:

Carbon footprint: Using wood as the primary raw material results in the storage of atmospheric carbon captured during the tree’s growth. Comparative analyses show that natural wood finishes have significantly lower greenhouse gas (GHG) emissions than alternatives such as:

- Ceramics: 60-75% fewer emissions

- Natural stone: 50-70% fewer emissions

- Petroleum-derived synthetic materials: 70-90% fewer emissions

Energy consumption: While the manufacturing process for high-performance panels is more energy-intensive than solid wood production, it still offers advantages over alternative materials:

- Pressure and temperature processes consume less energy than ceramic firing

- Efficiency in transport due to lower specific weight

- Lower total embedded energy per square meter installed

Sustainable forest management: Responsible manufacturers, such as Parklex Prodema, ensure that the wood used comes from sustainably managed forests, certified under standards like:

- PEFC (Programme for the Endorsement of Forest Certification)

- FSC (Forest Stewardship Council)

These certifications guarantee that wood extraction respects the forest’s regeneration capacity and ecological functions.

Environmental benefits in the built environment

Beyond their production environmental profile, integrating natural wood in wet environments provides benefits during the building’s lifecycle:

Hygrothermal comfort: Wood’s ability to partially regulate ambient humidity, even when technically treated, contributes to:

- Reduced extreme humidity fluctuations

- Lower reliance on climate control systems

- More comfortable environments with reduced energy consumption

Acoustic properties: Particularly relevant in spaces like bathrooms and wellness areas, where hard surfaces often cause reverberation issues. Wood finishes provide:

- Superior acoustic absorption compared to traditional materials like ceramics or stone

- Improved acoustic comfort in wellness spaces

- Reduced noise transmission to adjacent rooms

Health and well-being: Research in environmental psychology and biophilic architecture demonstrates the positive effects of natural materials in indoor environments:

- Measurable reduction in stress levels

- Enhanced perceived environmental quality

- Therapeutic effects in wellness-oriented spaces

9. Frequently asked questions about wood in wet environments

Does natural wood in bathrooms and kitchens require periodic varnishing?

No, when using high-performance wood panels like those developed by Parklex Prodema. These incorporate integrated treatments during manufacturing that provide permanent protection, eliminating the need for periodic maintenance with varnishes or oils. Unlike traditional solid wood, these products maintain their protective properties throughout their lifespan.

Is wood hygienic in spaces like kitchens or bathrooms?

Yes, contrary to traditional perceptions, scientific studies show that technically treated wood surfaces can be as hygienic as other materials considered “sanitary.” Modern treatments provide non-porous surfaces that prevent moisture and bacterial penetration, and many incorporate active antibacterial properties. Tests under standards like ISO 22196 demonstrate significant reductions in bacterial populations on these surfaces.

What is the difference between natural wood for exteriors and that specific to indoor wet environments?

While they share some base technologies, there are significant differences:

- Exterior products are designed to withstand UV radiation and variable weather conditions.

- Indoor wet environment products are optimized for resistance to condensation and constant humidity

- Indoor solutions prioritize stain resistance and antibacterial properties

- Indoor finishes maintain tactile and aesthetic characteristics closer to natural wood

Can high-performance wood for wet environments be installed in direct contact with running water, such as in showers?

It depends on the specific product and its certifications. High-density panels with natural wood finishes, like NATURHARDPANEL-W, can be installed in areas with frequent splash exposure, provided specific installation protocols ensure proper sealing of joints and junctions. For areas with constant exposure to running water, the manufacturer’s technical specifications and certifications must be verified.

How long does a natural wood finish last in high-humidity conditions?

High-quality natural wood panels are designed to maintain their technical and aesthetic properties throughout the building’s lifespan (over 20 years), even in high-humidity conditions, provided installation is done correctly. Real-world installations in demanding environments, such as kitchens, bathrooms, and spas in homes and hotels, as well as in particularly humid geographic areas, demonstrate the exceptional durability of these systems.

How do temperatures in areas like saunas affect technically treated natural wood finishes?

High-end wood panels are designed to withstand temperature ranges between -20°C and +80°C without significant dimensional changes. For specific applications like saunas, where higher momentary temperatures may occur, the product’s particular specifications and suitability for these extreme conditions must be verified. In general, treatments with thermosetting resins provide excellent thermal stability, surpassing that of untreated natural wood.