TABLE OF CONTENTS

- 1. Introduction to natural wood wall and ceiling paneling

- 2. Technical characteristics of interior panels

- 3. Installation systems for interior walls

- 4. Solutions for ceilings and suspended ceilings

- 5. Acoustic performance: sound control with natural wood

- 6. Fire resistance and applicable regulations

- 7. Durability and maintenance in high-traffic spaces

- 8. Integration of paneling in architectural projects

- 9. Sustainability and environmental certifications

- 10. Frequently asked questions

1. Introduction to natural wood wall and ceiling paneling

Incorporating natural wood paneling into interior spaces represents one of the most balanced solutions in contemporary architecture, combining design, comfort, and functionality. Wooden wall and ceiling paneling for interiors goes beyond mere aesthetics, offering essential technical qualities for conditioning interior spaces across various contexts.

Wood, as a living material, provides a chromatic and textural richness that synthetic materials cannot replicate. Its presence fosters a sense of well-being tied directly to the concept of biophilia, a trend that highlights the innate connection between humans and natural materials. However, traditional limitations of wood–such as resistance, maintenance, and adaptability to technical regulations–have been overcome through technological advancements in the manufacturing processes of natural wood panels.

Treated natural wood wall and ceiling paneling combines key aspects of contemporary architecture: material authenticity, high technical performance, and adaptability to the regulatory and functional demands of each project. This paneling enables the conditioning of diverse spaces, such as auditoriums, corporate offices, healthcare facilities, or commercial environments, while maintaining the characteristic warmth of wood alongside advanced technical performance.

2. Technical characteristics of interior panels

High-performance interior wood panels are constructed with a high-density core made of cellulose fibers impregnated with thermosetting resins. This core undergoes high-temperature and high-pressure compression processes, resulting in a compact material with significantly greater dimensional stability than traditional solid wood.

Layered composition

The layered composition of these panels includes:

- A surface layer of natural wood with the unique grain of each species.

- Protective technical coatings with a matte or satin finish.

- A core of cellulose fibers treated with thermosetting resins.

- A balancing back layer to ensure dimensional stability.

Standard thicknesses for interior applications range from 8 mm to 14 mm, with 10 mm being the most common for walls and 12 mm for suspended ceilings. Standard panel dimensions are approximately 2440 x 1220 mm, though customized solutions are available for specific projects.

Key technical characteristics

Moisture resistance is a distinguishing feature of these panels, maintaining dimensional stability in environments with variable humidity, making them suitable for spaces such as locker rooms or non-submerged wet areas. Tests according to the EN 438-2 standard show dimensional variation due to moisture exposure of less than 0.6% in the longitudinal direction and 0.3% in the transverse direction.

The resulting density exceeds 1,350 kg/m³, providing exceptional impact resistance with values above 1.4 N/mm² according to standardized tests. This characteristic makes them ideal for high-traffic areas where durability is a critical requirement.

For both commercial and institutional spaces, high-performance natural wood panels offer a scratch resistance of Grade 4 per the EN 438-2 standard, ensuring the preservation of their appearance even in intensive-use environments without the need for periodic maintenance or post-installation varnishing.

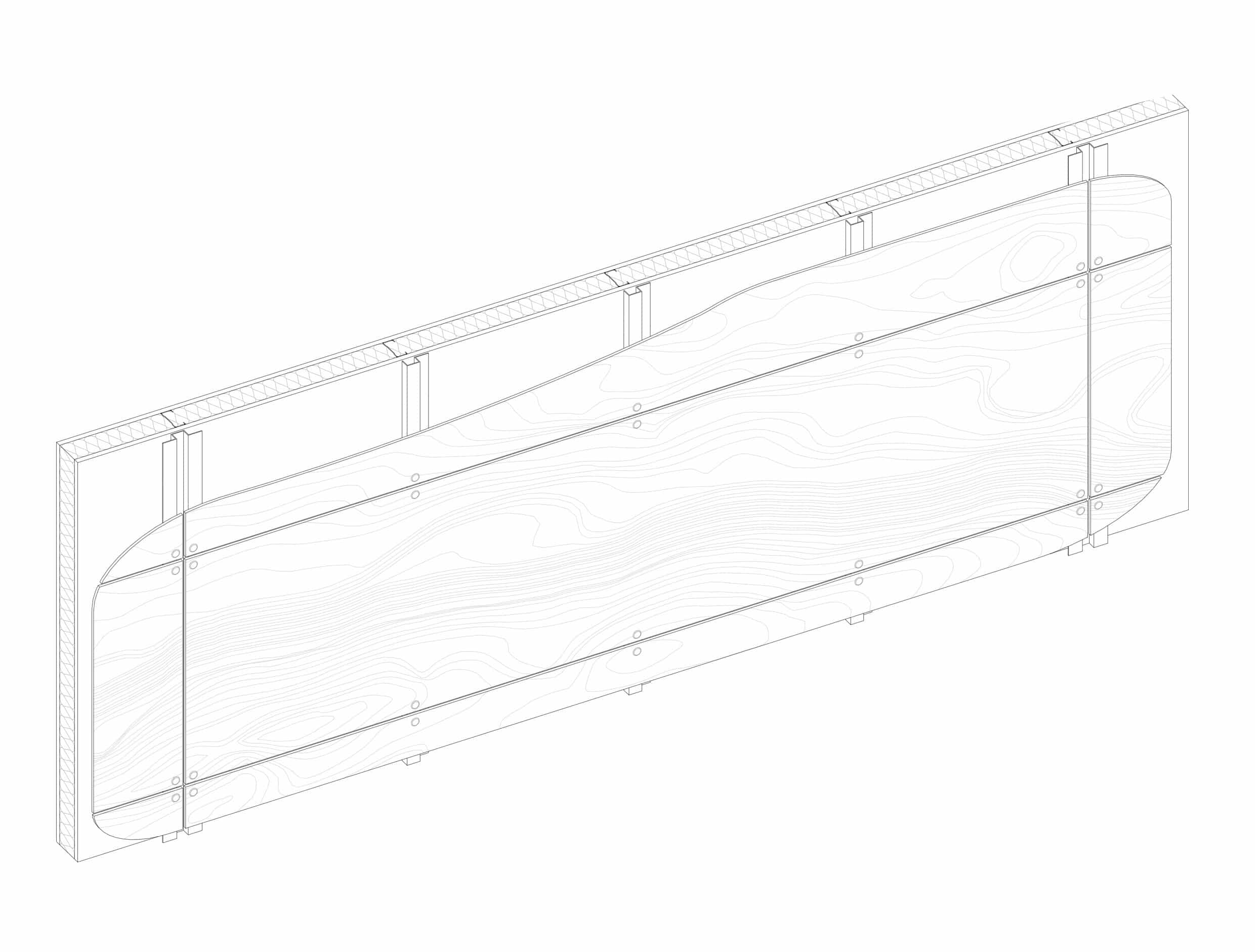

3. Installation systems for interior walls

Installation systems for high-performance natural wood wall panels can be classified into three main categories, each with its own technical and aesthetic characteristics.

Visible fastening system with screws or rivets

This system uses visible mechanical fastenings, such as screws or rivets, painted in tones similar to the wood of the panel. Installation is carried out on vertical channels that create a technical cavity between the panel and the wall, allowing for the passage of utilities or the inclusion of insulating material.

For panels with a thickness of 8–10 mm, a maximum distance of 600 mm between channels is recommended, while for 12 mm panels, this distance can be increased to 800 mm. The spacing between fastenings should be proportional to the panel thickness, maintaining a distance of 20–40 mm from the panel edge to the center of the fastening point.

It is essential to pre-drill the panel with a diameter slightly larger than that of the fastening to allow for the natural movement of the wood. Each panel should have a single fixed point, preferably located at the center, while the remaining points should be floating to accommodate micro-movements of the material.

Concealed fastening system with plugs

For projects where aesthetics take precedence over technical considerations, the concealed fastening system with plugs ensures visual continuity of the paneling. This system uses plugs of the same finish as the panel, with a 14 mm diameter, to conceal the mechanical fastenings.

This method requires panels with a minimum thickness of 10 mm and must be installed with special care to ensure that the drilling does not penetrate the visible face of the panel. The cavity created after fastening is partially filled with silicone sealant before inserting the wooden plug.

Concealed fastening system with hooks

Concealed fastening systems with hooks offer significant advantages in large-scale projects, as they allow for easy disassembly to access utilities behind the wall. This system uses horizontal channels anchored to a primary vertical subframe.

The panels incorporate metal hooks screwed to their back face, which slot into the horizontal channels. Proper alignment is achieved using leveling screws located at the top of the hooks. To ensure the stability of the assembly, the central hook on the top row must be fixed to the horizontal channel with a self-tapping screw.

4. Solutions for ceilings and suspended ceilings

Natural wood suspended ceilings provide a comprehensive solution for the acoustic and aesthetic conditioning of interior spaces. These systems combine the visual warmth of wood with advanced technical performance in terms of installation, maintenance, and acoustic behavior.

Residential Building Mediterráneo 176 / Golden View Residence

For suspended ceilings, installation can be carried out using any of the systems described above, although hook or clip fastening systems are particularly suitable as they facilitate subsequent access to utilities in the plenum. The spacing between channels is calculated based on the panel thickness:

- For panels of 8–10 mm: maximum distance of 600 mm between channels

- For panels ≥12 mm: maximum distance of 800 mm between channels

A key technical aspect in the installation of suspended ceilings is accounting for the system’s own weight. With an approximate density of 1,350 kg/m³, 10 mm panels have an approximate weight of 13.5 kg/m². This data must be considered when designing the supporting structure for the suspended ceiling.

Suspended ceilings with planks are a variant that allows for modulation of the ceiling’s visual continuity and enhances acoustic performance by incorporating absorbent material in the plenum. Standard plank dimensions include widths of 136 mm, 188 mm, and 290 mm, with a standard length of 2440 mm and a thickness of 8 mm.

The integration of utilities such as lighting fixtures, air conditioning diffusers, or fire sprinklers requires precise cutouts in the panels. These cutouts should preferably be made in a workshop using CNC milling machines to ensure cutting precision and avoid splintering.

5. Acoustic performance: sound control with natural wood

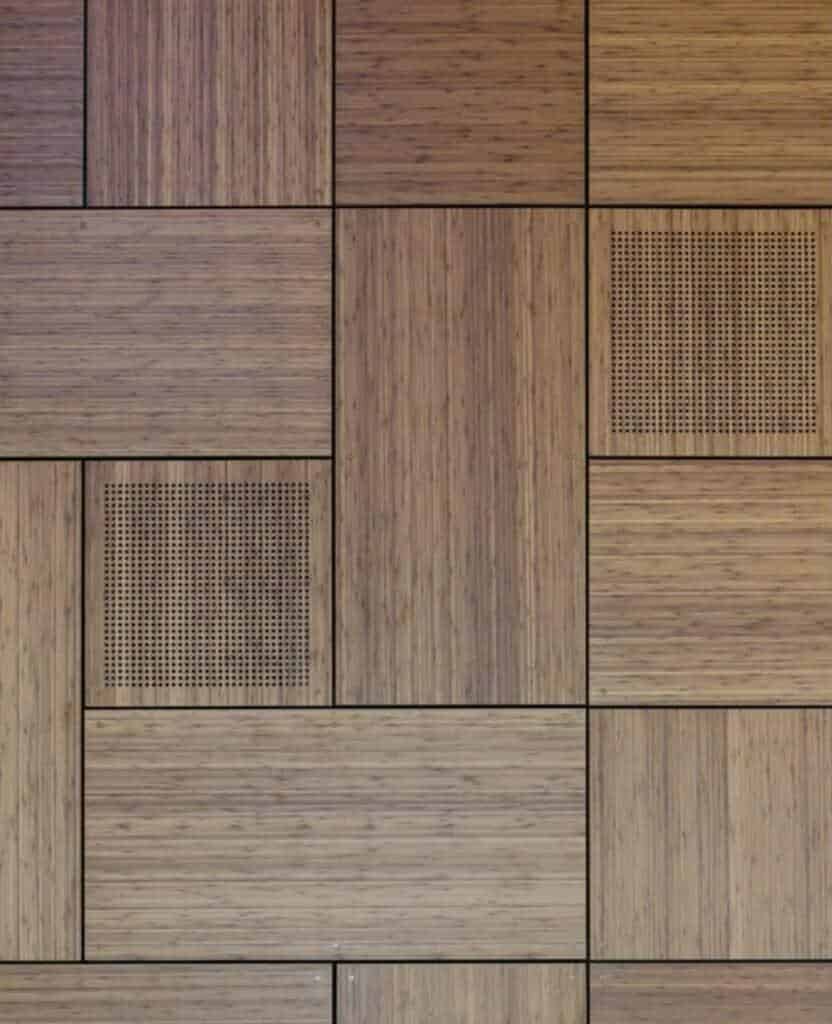

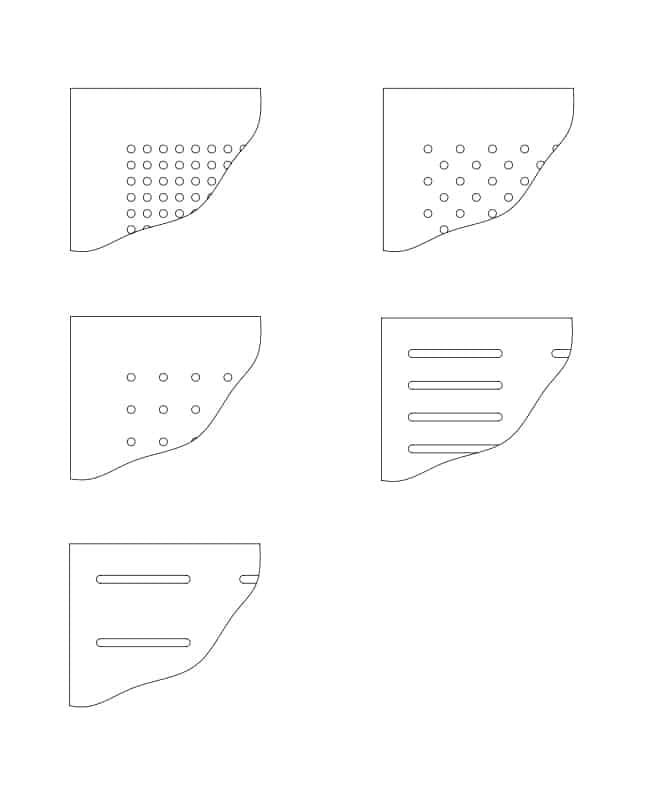

The acoustic performance of high-performance natural wood panels is one of their primary added values in architectural applications. These materials enable effective sound control strategies through two complementary approaches:

Acoustic absorption

Sound absorption is achieved through perforations or slots in the panels, combined with absorbent material in the rear cavity. Acoustic wood panels can achieve absorption coefficients (αw) of up to 0.85 (Class B according to EN ISO 11654) when specifically designed for this function.

The most common perforation types include:

- Circular micro-perforations (1–2 mm diameter, 5–16 mm spacing)

- Linear slots (2–4 mm width, 16–32 mm spacing)

- Variable diameter perforations (random pattern for optimized acoustics)

Acoustic insulation

Acoustic insulation is achieved through the panel’s mass combined with the installation system. Systems with a subframe and absorbent material in the cavity can improve the acoustic insulation of the base wall by 6–8 dB, depending on the specific configuration.

For spaces such as auditoriums, conference rooms, or recording studios, panel configurations can be designed with specific acoustic performance tailored to different frequency ranges. This advanced acoustic design requires a detailed study of the space’s characteristics and functional needs.

6. Fire resistance and applicable regulations

The fire performance of interior paneling is a critical factor in contemporary architectural design, particularly in public buildings. Natural wood panels have evolved to meet the most stringent regulatory requirements while preserving the aesthetic warmth of wood.

Fire-retardant natural wood panels for interiors incorporate a fiberglass core impregnated with synthetic resins and mineral fillers, providing significantly higher non-combustibility properties compared to conventional wood.

The fire reaction classification according to the European standard EN 13501-1 places these panels in the following categories:

- B-s1,d0 for standard panels

- A2-s1,d0 for panels with a specific fire-retardant core

This classification indicates that the panels:

- Contribute very minimally to fire spread (B) or are virtually non-combustible (A2)

- Produce very limited smoke emission in terms of quantity and speed (s1)

- Do not produce flaming droplets or particles (d0)

It is essential to evaluate fire resistance holistically, considering not only the paneling but the entire construction assembly. For this reason, manufacturers provide specific test results for different installation configurations.

The use of fire-retardant panels is mandatory in evacuation routes, public areas, and high-risk spaces. For high-rise buildings, regulations are particularly stringent, requiring materials classified as A2-s1,d0.

7. Durability and maintenance in high-traffic spaces

High-performance natural wood panels stand out for their exceptional durability, even in high-traffic environments. This characteristic is essential in spaces such as hotels, offices, museums, or airports, where maintenance must be minimized without compromising aesthetics.

The surface resistance of these panels is due to their protective coating, which prevents wear and facilitates cleaning. Unlike traditional solid wood, these panels do not require periodic varnishing or specific maintenance treatments, significantly reducing operational costs over their lifespan.

For regular cleaning, warm water with neutral liquid detergent applied with a soft cloth is sufficient, avoiding dry wiping. For stubborn stains, a cloth dampened with universal solvent or isopropyl alcohol can be used, after testing compatibility on an inconspicuous area.

The following should be avoided:

- Detergents with abrasive particles

- Aggressive solvents such as acetone, xylene, or MEK

- Steam cleaners or external heat sources

The surface of these panels has non-stick properties that prevent the permanent adhesion of spray paints, facilitating the removal of graffiti using specific products followed by cleaning with soapy water and rinsing with clean water.

8. Integration of paneling in architectural projects

The strategic incorporation of wood paneling in architectural projects enables visual continuity between different spaces and elements. This integration can be approached from various perspectives:

Aesthetic continuity between exterior and interior is an increasingly relevant architectural concept. Using the same wood species for both façade cladding and interior paneling creates a seamless transition that blurs the boundaries between these spaces. To ensure this aesthetic coherence, it is essential to select wood species with stable performance in both interior and exterior environments.

In the single-family home designed by Indievisual AG, architectural integration is achieved through the use of Grey Eucalyptus natural wood panels. The eucalyptus soffit extends as a continuous surface from the interior to the exterior, dissolving the boundaries between the two spaces and blending with the natural forest surroundings, reinforcing the building’s connection to its context.

Coordination with flooring is equally important for achieving a cohesive architectural environment. The availability of floors and paneling in the same wood species allows for the development of spaces with a unified material language. This strategy is commonly seen in boutique hotels and high-end corporate spaces, where material coherence strengthens spatial identity.

For transitional areas such as lobbies or reception spaces, material continuity between floor, wall, and ceiling creates an immersive experience that enhances spatial perception. This holistic approach requires careful planning of joints and transitions between the various covered surfaces.

9. Sustainability and environmental certifications

The commitment to environmental sustainability is currently a determining factor in the selection of materials for architectural projects. Natural wood panels offer verifiable environmental credentials through independent certifications.

The PEFC (Programme for the Endorsement of Forest Certification) certification ensures that the wood used comes from sustainably managed forests. This certification system guarantees full traceability of the chain of custody from the forest to the final product, verifying that forestry practices meet environmental sustainability, economic viability, and social responsibility criteria.

Manufacturers committed to sustainability provide Environmental Product Declarations (EPDs per ISO 14025), which offer quantified and verifiable information about the material’s environmental impact throughout its lifecycle.

The environmental impacts quantified in EPDs include:

- Global warming potential (carbon footprint)

- Acidification potential

- Eutrophication potential

- Ozone depletion potential

- Consumption of primary energy resources

These declarations are particularly relevant for projects aiming for LEED, BREEAM, or WELL certifications.

10. Frequently asked questions

Do high-performance natural wood panels require periodic maintenance treatments?

No, these panels do not require varnishing or specific maintenance treatments. Their factory-applied protective layer ensures long-term durability and resistance. Regular cleaning with warm water and neutral detergent is sufficient to preserve their original appearance.

Can this paneling be installed in humid areas such as bathrooms or spas?

High-performance natural wood paneling is suitable for non-submerged humid areas. Its moisture resistance makes them appropriate for bathrooms, locker rooms, or spa areas, provided they are not in constant contact with water. For these applications, it is advisable to use visible fastening systems with stainless steel screws.

What is the difference between slotted and micro-perforated acoustic panels?

Both systems enhance acoustic absorption but offer different performance depending on the frequency range. Micro-perforated panels are more effective for mid-to-high frequencies, while slotted panels perform better for mid-to-low frequencies. The choice depends on the specific acoustic study of the space and its intended use.

Are these panels compatible with radiant heating systems?

Yes, the panels can be installed on walls with radiant heating systems, maintaining a technical cavity of at least 20 mm between the panel and the heating element. It is recommended to limit the surface temperature to a maximum of 45°C to avoid excessive material contraction.

How does the passage of time affect the appearance of this paneling?

Unlike traditional solid wood, these panels maintain their appearance with minimal chromatic variations over time. The protective layer prevents the yellowing and oxidation typical of untreated wood. In interiors without direct exposure to ultraviolet light, chromatic stability is particularly notable.