1. Introduction to Natural Wood Planks

The incorporation of natural wood planksfor contemporary building facades represents one of the most significant trends in modern architecture. This exterior wood cladding system has undergone remarkable technological evolution in recent decades, transitioning from a primarily decorative element to a comprehensive solution that effectively addresses multiple architectural requirements.

Wood, an ancient construction material, has reclaimed a starring role thanks to technical advancements that have overcome its traditional limitations for exterior use. The development of technically advanced wood planksystems has made it possible to combine the warmth and natural expressiveness of this material with exceptional durability, strength, and sustainability.

In an architectural context where energy efficiency, sustainability, and identity are core values, natural wood planksoffer a complete and versatile solution. This article explores in depth the possibilities these systems provide as an architectural solution for contemporary facades, addressing their aesthetic benefits, technical performance, and environmental contributions.

2. Architectural Benefits of Natural Wood Planks

Aesthetic Versatility and Expressiveness

Natural wood planks bring a unique aesthetic dimension to architectural facades. The inherent visual richness of this material – through its tonal variations, grain, and texture – gives each project a distinctive and unrepeatable character. The planks allow architects to play with the facade’s materiality, creating surfaces that shift in appearance depending on the angle of natural light and the observer’s perspective. Moreover, wood establishes a direct connection with nature, introducing warmth into urban environments often dominated by cold materials like concrete, metal, or glass. This biophilic quality has a proven positive impact on the well-being of users and passersby, creating more human and welcoming spaces.

Design Possibilities

Plank systems offer architects a wide range of creative possibilities. The configuration of the planks can be varied in terms of:

- Dimensions: Available in different widths (typically between 100 and 300 mm) and lengths up to 3000 mm, allowing adaptation to the specific proportions of each project.

- Rhythms and Patterns: The arrangement of planks can create varied rhythmic effects, from regular sequences to more dynamic or random compositions.

- Orientation: Horizontal, vertical, or even diagonal installation, with the possibility of combining orientations.

- Spacing: The distance between planks can be adjusted to control the facade’s visual transparency and permeability.

- Finishes: A variety of wood species and surface treatments allow for different tones and textures.

Solar Control and Energy Efficiency

One of the most notable functional benefits of wood planks is their ability to act as passive solar control elements. Through proper design – considering factors such as building orientation, local climate, and seasonal solar angles – planks can:

- Filter direct solar radiation in summer, significantly reducing unwanted heat gains.

- Allow sunlight to pass in winter, when the solar angle is lower, maximizing natural heat contribution.

- Regulate natural light entry, improving indoor visual comfort and reducing reliance on artificial lighting.

Recent studies show that a facade equipped with a well-designed plank system can reduce energy consumption related to climate control and lighting by up to 30%.

Creation of Transitional Spaces

Wood planks enable the creation of compelling intermediate spaces between interior and exterior. By modulating visual and solar permeability, they create transitional areas that enrich the architectural experience. These filtered spaces allow:

- Privacy in specific areas without compromising natural light entry.

- Dynamic light and shadow effects throughout the day.

- Visual “breathing spaces” that subtly connect the building with its surroundings.

- Partially protected outdoor spaces that expand the building’s functional possibilities.

Contribution to Building Identity

The use of natural wood planks significantly contributes to a building’s architectural identity. The distinctive materiality of wood provides personality and immediate recognition. Additionally, the planksystem can become a core element of the project’s architectural language, establishing a dialogue with the surrounding urban or natural context.

3. Advanced Technical Solutions for Exterior Wood Planks

Composition and Technology

Natural wood planks for exterior use have undergone significant technological advancements. Modern advanced systems available on the market typically consist of:

- Stabilizing Core: Often high-density, made from wood fibers or resin-impregnated paper compressed at high pressure and temperature. Some systems also use fiberglass cores for applications requiring higher fire resistance.

- Natural Wood Veneer: Sourced from various tree species and treated to enhance its natural aesthetic qualities.

- Protective Coating: A surface layer, typically made of synthetic resins or specific treatments, providing protection against UV radiation, moisture, atmospheric agents, and vandalism.

This advanced composition overcomes the main limitations of natural wood in exterior applications, such as deformation, dimensional changes, degradation due to moisture and UV radiation, and the need for periodic maintenance.

Dimensions and Available Options

Current plank systems for facades offer various options to meet the specific needs of each project: Standard Dimensions:

- Available Widths: Typically between 100 and 300 mm

- Lengths: Vary by manufacturer, generally up to 3000 mm

- Thicknesses: Between 6 and 30 mm, depending on the system and application

Finishes: Available in numerous species (oak, ayous, eucalyptus, heat-treated pine, etc.) and finishes ranging from natural tones to more specific colors achieved through staining or thermal treatments. Special Formats: Some manufacturers offer customized dimensions for specific projects.

Installation Systems

There are three main installation systems, each with specific characteristics:

1. Horizontal System

Designed for horizontal plank installation, typically using clips or specific channels that ensure:

- Constant ventilation between planks

- Quick and easy installation

- Individual plank removal if needed

- Uniform joints between planks

- Compatibility with metal or wooden subframes

2. Vertical System

Allows for vertical plank installation, using:

- Specific fastening elements for vertical mounting

- Retention components to prevent longitudinal sliding

- Double subframe system to ensure proper ventilation

- Uniform joints between planks

- Versatility and adaptability to various facades

3. Lap Siding System

Offers a traditional horizontal overlapping board appearance, providing:

- Aesthetic depth and texture effect

- Excellent weather protection

- Installation with specific elements enabling overlap

- Controlled expansion joints using specialized tools

Technical Performance and Certifications Advanced exterior plank systems undergo rigorous testing to certify their technical performance:

- Weather Resistance: Accelerated aging tests per standards like EN 438-6, ensuring durability against UV radiation and weather conditions.

- Dimensional Stability: Verification of performance under extreme temperature and humidity variations, with minimal dimensional changes (typically less than 1%).

- Impact Resistance: Classification according to standards like EN 438-2, ensuring suitability for accessible areas.

- Performance combating fire: Classifications per EN 13501-1, with various options depending on project requirements.

- Durability: Manufacturers typically offer warranties ranging from 10 to 25 years, depending on installation and exposure conditions.

The most advanced systems hold international certifications such as ETA (European Technical Assessment), DIT Plus (Documento de Idoneidad Técnica Plus), and CCRR (Code Compliance Research Report) for the U.S. market.

Compatibility with Construction Systems

Exterior wood planks are compatible with various contemporary construction systems:

- Ventilated Facades: Seamless integration into complete ventilated facade systems.

- Building Rehabilitation: Applicable over existing structures with minimal adaptations.

- ETICS (External Thermal Insulation Composite Systems): Can be combined with external thermal insulation systems.

- Hybrid Envelopes: Compatible with other materials such as glass, metal, or stone.

- Specific Applications: Adaptable to elements like sunshades, louvers, parapets, or sloped roofs with appropriate pitch.

4. Sustainability and Lifecycle

Sustainable Sourcing of Raw Materials

Sustainability begins with the responsible sourcing of the wood used. The most advanced systems incorporate:

- Forestry Certifications: Certifications such as PEFC or FSC ensure that the wood comes from sustainably managed forests, with full traceability from source to final product.

- Responsible Selection: Tree species from controlled growth and guaranteed reforestation.

- Resource Optimization: Manufacturing processes that maximize wood utilization, using thin veneers over composite cores, thereby reducing the consumption of solid wood.

Comparative Analysis with Other Materials

Compared to other facade cladding materials, natural wood planks offer significant environmental advantages:

| Material | Embodied Energy (MJ/kg) | Carbon Footprint (kg CO₂ eq/kg) | Renewable | Recyclable |

| High-Performance Wooden Planks | 15-20 | -1.2 to -0.8* | High | High |

| Aluminum | 160-220 | 11-13 | None | High |

| PVC | 70-95 | 2.5-3.5 | None | Medium |

| Fiber Cement | 10-30 | 1.2-2.0 | None | Low |

| Ceramic | 8-12 | 0.8-1.5 | Low | Medium |

High-performance natural wood planks stand out particularly for:

- Positive Carbon Balance: Wood sequesters CO₂ during its growth, offsetting emissions generated during processing.

- Low Embodied Energy: Requires significantly less energy to produce compared to materials like aluminum or plastic composites.

- Renewable Resource: Unlike materials derived from finite resources, wood is renewable when sourced from responsibly managed forests.

Environmental Impact and Carbon Footprint

The lifecycle analysis (LCA) of advanced wood plank systems demonstrates a favorable environmental channel:

- Carbon Sequestration: Each square meter of facade with wood planks stores approximately 5-7 kg of CO₂ equivalent.

- Reduction of Urban Heat Island Effect: Wood’s lower thermal absorption compared to materials like metal or ceramic helps mitigate the urban heat island effect in city environments.

- Improved Building Energy Performance: Contribution to energy efficiency through passive solar control significantly reduces the building’s operational emissions throughout its lifecycle.

- Optimized Production: Leading manufacturers implement production processes that optimize energy resource use and minimize waste.

Longevity and Extended Lifecycle

The durability of technically advanced wood planks is another key factor in their sustainability channel:

- Extended Service Life: Applied technology ensures durability exceeding 25-30 years without significant degradation in the most advanced solutions.

- Minimal or No Maintenance: Unlike traditional wood, many systems do not require periodic treatments such as varnishing or repainting, eliminating the environmental impact associated with these processes.

- Resistance to Extreme Conditions: Stable performance under severe climatic variations, extending service life even in harsh environments.

5. Application Examples and Success Stories

Residential Projects

Natural wood planks have demonstrated their versatility and effectiveness in numerous residential projects, ranging from single-family homes to apartment complexes:

- Bioclimatic House in Barcelona (1): This residential project uses adjustable horizontal planks to create a dynamic envelope that responds to seasonal needs. The system regulates solar radiation intake based on the time of year, optimizing the building’s thermal performance while maintaining a visual connection with the Mediterranean surroundings.

- Residential Complex in Oslo (2): The MAD building, located in the Opera Quarter district, combines residential and commercial spaces in a 15-story tower. The movable facade, clad with Rustik natural wood panels, allows residents to control sunlight entry. This envelope not only defines the building’s aesthetic identity but also withstands Norway’s demanding climate due to its high resistance to radiation, dirt, and atmospheric agents, enriching the spatial experience from both sides.

Public and Educational Buildings

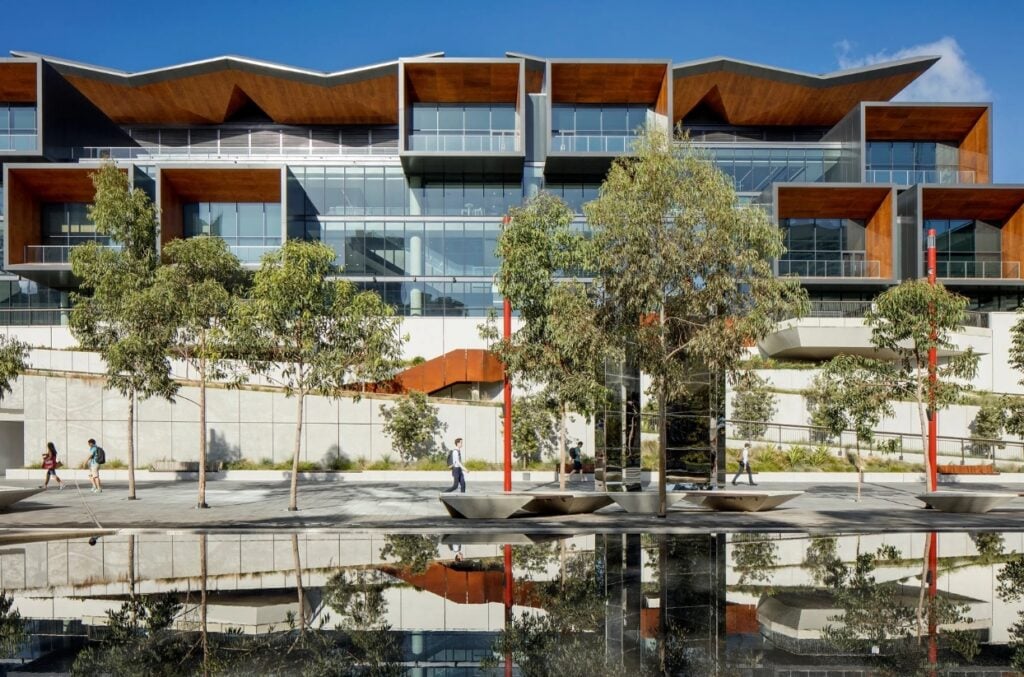

Public spaces particularly benefit from the aesthetic and functional qualities of wood planks:

- Sydney International Convention Centre (1): This cultural center is part of the city’s harbor regeneration plan and houses Australia’s largest exhibition venue. Parklex Prodema panels in a Rustik finish adorn the eastern facade, the most iconic side, which includes both the theater and the exhibition center. The use of faceted solutions and natural wood exterior suspended ceilings softens the visual impact of its monumental scale, creating a welcoming image connected to the urban and natural environment of Tumbalong Park.

- Parisian Gallery (2): This gallery stands out for its façade clad with Parklex Prodema architectural panels in a Black finish, offering a rich, maintenance-free texture. The customized installation features perpendicular grain patterns that contrast with vertical beams, creating a unique visual rhythm. The deep black cladding establishes an elegant contrast with the adjacent classically styled buildings, projecting a distinctive and contemporary identity while maintaining a connection to its historical context.

Applications in Extreme Environments

The advanced technical performance of modern systems allows their use in demanding environmental conditions:

- Rica Bakklandet Hotel (1): Located by the river in the coastal city of Trondheim, this hotel combines Nordic design with durable materials. The ventilated facade system with Parklex Prodema panels in Antra finish protects against humidity and salinity in the environment while maintaining its appearance without maintenance. The use of natural wood adds warmth to a sober and modern architecture, capable of withstanding the extreme conditions of northern Europe without compromising aesthetic quality or technical functionality.

- Cliffside Residence (2): This residence overlooking Port Washington Bay adapts to a steep terrain with an L-shaped configuration that optimizes privacy and views. The exterior facade is clad with Parklex Prodema panels in Rustik finish, highly resistant to the marine climate. Inside, the same panels are applied to ceilings and walls, creating visual continuity and material coherence. The chosen solution combines natural aesthetics with technical durability, ideal for a challenging and exposed environment.

Renovations and Rehabilitations

The lightweight and adaptable nature of plank systems makes them particularly suitable for interventions on existing buildings:

- Banff Centre, Sally Borden Building (1): Located in a protected natural environment, this multipurpose center was renovated to enhance its landscape integration and energy efficiency. Parklex Prodema panels in Rustik finish provide a warm aesthetic that harmonizes with the alpine surroundings. Made from sustainable raw materials, they improve the building’s thermal insulation against the cold temperatures of the Canadian national park, reinforcing its environmental commitment without compromising design.

- Frisco Public Library (2): This project transforms an old Texas factory into a dynamic, community-oriented knowledge hub. The facade incorporates Parklex Prodema panels in Mustard finish, installed using an overlapping plank system that pays homage to vernacular architecture. Its color engages with the native vegetation of the surrounding landscape. The result is a durable, maintenance-free facade that combines tradition, functionality, and contemporary aesthetics in a single architectural gesture.

6. Technical Guide for Selection and Installation

Considerations for Choosing the Right System

Selecting the most appropriate planksystem requires considering various factors.

Building Orientation and Climatic Conditions:

- Analysis of solar path and prevailing winds

- Evaluation of precipitation and UV radiation intensity

- Consideration of relative humidity and environmental salinity

Aesthetic and Visual Requirements:

- Definition of the desired transparency/opacity effect

- Selection of wood species and finish based on the project’s color palette

- Consideration of plank patterns and rhythm in relation to the building’s volumetry

Specific Technical Requirements:

- Analysis of regulatory requirements (fire resistance, acoustics, etc.)

- Evaluation of maintenance and accessibility needs

- Compatibility with other facade elements (windows, trims, etc.)

Type of Available Subframe:

- Assessment of the existing load-bearing structure

- Determination of the most suitable subframe type (metal or wood)

- Analysis of specific points and required anchors

Key Aspects of the Installation Process Proper installation of planksystems ensures optimal performance.

Pre-Installation Preparation:

- Verification of the flatness and plumbness of the supporting surface

- Checking anchor points and mechanical strength

- Precise layout of channel and plank positions

Subframe Installation:

- Placement of vertical channels with appropriate spacing based on calculations

- Ensuring verticality and alignment

- Providing a ventilated cavity of at least 20 mm

- Installing waterproofing elements when necessary

Plank Installation:

- Use of specific tools and appropriate fastening clips

- Adherence to expansion joints between planks

- Consideration of material expansion/contraction

- Progressive installation, controlling alignment and leveling

Finishes and Specific Points:

- Proper resolution of junctions with other elements (windows, cornices, etc.)

- Installation of base and top channels

- Appropriate treatment of corners as per project specifications

- Temporary protection during the remainder of construction work, where necessary

Specific Recommendations by Typology and Climate

Buildings in Coastal Environments:

- Prioritize systems with AISI 316 stainless steel fasteners

- Use aluminum subframes with marine-grade treatment or stainless steel

- Maintain enhanced ventilation in the air cavity

Areas with High Solar Radiation:

- Consider lighter finishes to reduce thermal absorption

- Evaluate plank orientation and spacing to optimize solar protection

- Ensure continuous ventilation to prevent overheating

Urban Areas with Pollution:

- Select finishes with reinforced anti-graffiti treatment

- Plan for accessibility for periodic cleaning, where necessary

- Consider installing protective elements in accessible areas

Extremely Cold Climates or Areas with Heavy Snowfall:

- Increase fasteners in areas prone to ice/snow accumulation

- Provide adequate drainage for horizontal elements

- Reinforce the subframe to support additional loads

Regulations and Technical Requirements

The design and installation of planksystems must comply with various regulations.

Structural Safety:

- CTE DB-SE-AE: Actions in Building (Spain)

- ASCE 7: Minimum Design Loads for Buildings and Other Structures (USA)

- Eurocode 1: Actions on Structures (Europe)

Fire Protection:

- CTE DB-SI: Fire Safety (Spain)

- EN 13501-1: Fire Classification of Construction Products (Europe)

- NFPA 285: Standard Fire Test Method (USA)

Acoustic Insulation:

- CTE DB-HR: Noise Protection (Spain)

- ISO 140: Measurement of Acoustic Insulation in Buildings (International)

Sustainability and Energy Efficiency:

- CTE DB-HE: Energy Saving (Spain)

- LEED v4: Leadership in Energy and Environmental Design (International)

- BREEAM: Building Research Establishment Environmental Assessment Method (International)

Available Technical Support Resources

Professionals can utilize various resources to optimize the design and installation process.

Specialized Technical Consultations

- Personalized advice from manufacturers for specific projects

- Consultants specializing in architectural envelopes

- Professional associations in the wood sector

Technical Documentation

- Detailed technical data sheets with characteristics and performance

- Construction details in CAD/BIM formats

- Specifications for projects and tender documents

Training Resources

- Technical seminars for professionals

- Specialized publications and monographs

- Specific courses on wooden facade systems

7. Frequently Asked Questions

What are the main fastener systems for wood planks?

Fastenersystems for plankscan be classified into two main groups.

Visible FastenerSystems:

- Use screws or rivets visible from the exterior, typically coated in the same color as the planks

- Allow for simple and direct assembly onto the subframe

- Facilitate individual plank removal for repair or replacement

- Require proper pre-drilling to accommodate material expansion and contraction

- Provide high resistance to wind suction

Hidden Fastener Systems:

- Fastener elements are concealed behind the planks or within the joints between them

- Use special clips or brackets attached to the subframe

- Offer a cleaner, minimalist finish with no visible metal elements

- Some systems allow front-facing assembly and disassembly of planks

In addition, specific solutions such as hidden hook systems for special applications or pre-assembled modules for large surfaces are available. The choice of system should consider factors such as wind exposure, accessibility for maintenance, and the project’s aesthetic requirements.

What warranties does Parklex Prodema offer for its plank systems?

Parklex Prodema guarantees the quality and durability of its plank systems with specific warranties:

- 10-Year Standard Warranty: For installations with an inclination of up to 30° from the vertical plane. This warranty covers aspects such as color stability, coating adhesion, and panel structural integrity.

- 5-Year Warranty: For installations with an inclination greater than 30° from the vertical plane, where exposure to solar radiation and elements is more intense.

These warranties are subject to:

- Proper installation following the manufacturer’s technical instructions

- Use of original or recommended fastener systems

- Basic recommended maintenance (periodic cleaning)

Additionally, Parklex Prodema provides technical support throughout the product’s lifespan, including advice on maintenance and potential repairs. It’s worth noting that the products are backed by international certifications such as ETA (European Technical Assessment) and CCRR (Code Compliance Research Report) for the US market, validating their quality and performance. For projects with special requirements, Parklex Prodema can evaluate customized or extended warranties. Complete warranty documentation is available through their distribution network or technical department.

How does the use of wood planks impact a building’s energy rating?

The use of wood plankscan positively influence a building’s energy rating in several ways.

Reduction in Energy Demand:

- As shading elements, properly designed planks can reduce solar gains by 30-40% in summer

- This reduction in direct radiation decreases the need for active cooling

- In movable or adjustable configurations, they optimize solar capture in winter

Improved Thermal Performance:

- Planks installed as part of a ventilated facade system enhance the building’s insulation

- The ventilated cavity reduces the facade’s surface temperature in summer

- This effect can lead to a 10-15% reduction in cooling demand

Contribution to LEED, BREEAM, or VERDE Ratings:

- The use of certified wood earns points in sustainable materials categories

- Contribution to indoor thermal comfort is positively evaluated

- The favorable lifecycle of wood contributes to reducing the building’s overall carbon footprint

To maximize these benefits, the plank system must be properly sized and specifically designed for the building’s climatic conditions and orientation. Energy simulation tools allow for precise quantification of the specific impact on each project

What is the expected durability of natural wood planks for exterior use?

Advanced wood plank systems are designed to offer a service life exceeding 25-30 years under normal exposure conditions. Thanks to their technologically advanced composition and specific surface treatments, they maintain their aesthetic and functional characteristics over an extended period without significant degradation. Leading manufacturers typically offer warranties ranging from 10 to 25 years, depending on installation and exposure conditions.

Do exterior wood planks require periodic maintenance?

Unlike traditional natural wood, technologically advanced systems require minimal or no maintenance. There is no need for periodic varnishing, oiling, or painting. The only recommended maintenance is occasional cleaning with water and mild detergent to remove accumulated surface dirt, particularly in urban or industrial environments with higher pollution levels.

How do extreme weather conditions affect natural wood planks?

Modern systems are designed and tested to withstand extreme weather conditions, with exceptional performance against:

- Intense UV Radiation: No significant discoloration due to surface protections.

- Humidity and Rain: Maintain dimensional stability without significant moisture absorption.

- Freeze-Thaw Cycles: No delamination or detachment due to these conditions.

- Saline Environments: Adequate resistance in coastal settings (specific fasteners are recommended in these cases).

What sets technically advanced planks apart from other wood facade solutions?

The main difference lies in their technologically advanced composition. While traditional solutions use treated solid wood, advanced systems feature:

- Significantly superior dimensional stability

- Exceptional resistance to degradation from atmospheric agents

- Consistent and predictable long-term performance

- Minimal or no maintenance requirements

- Availability of advanced technical certifications

Are wood planks compatible with External Thermal Insulation Composite Systems (ETICS)?

Yes, wood planks can be installed in combination with ETICS, though specific considerations are required. Typical installation involves:

- Fastener the subframe through the insulation to reach the load-bearing support

- Using specific anchors to minimize thermal bridges

- Properly designing the ventilated cavity between the ETICS and the planks

- Coordinating with the ETICS to address specific junction points

What types of buildings are most suitable for installing wood planks?

Wood planks are suitable for virtually any building type, including:

- Residential buildings, both single-family and multi-family

- Public facilities (educational, cultural, healthcare, etc.)

- Office and corporate buildings

- Commercial and hospitality facilities

- Renovations and rehabilitations of existing buildings

They are particularly appropriate for projects that prioritize sustainability, connection with nature, passive solar control, and distinctive architectural identity.

How do wood planks perform in fire conditions, and what are their classifications?

Advanced plank systems typically have classifications of B-s1,d0 or C-s2,d0 according to the European standard EN 13501-1, which means:

- B/C: Limited or very limited contribution to fire

- s1/s2: Limited or moderate smoke production

- d0: No production of flaming droplets/particles

This classification allows their use in most facade applications in compliance with current regulations. For specific fire resistance requirements, versions with fire-retardant cores reinforced with fiberglass are available, further improving fire performance.

Can planks be installed on curved surfaces or complex geometries?

Yes, many plank systems can adapt to curved surfaces and complex geometries. The possibilities depend on the specific system:

- Large-radius curved surfaces: Most systems can adapt to gentle curvatures (radii greater than 3-4 meters) by shortening plank lengths or reducing the distance between channels.

- Medium-radius curved surfaces: Some systems are designed to accommodate medium curvatures (between 1 and 3 meters) using shorter planks or special anchoring systems.

- Tight curvatures: For radii less than 1 meter, some manufacturers offer pre-curved pieces or articulated systems that can follow complex geometries.

For each specific project, it is advisable to consult with manufacturers regarding the exact possibilities and limitations of each system.